Sigma Weld ProSeries is State of the art digital welding technology operating at 150kHz. Ensures very quick response time and better welding performance each time. The modular technology helps increase duty cycle upto 100% and ensures maximum machine uptime.

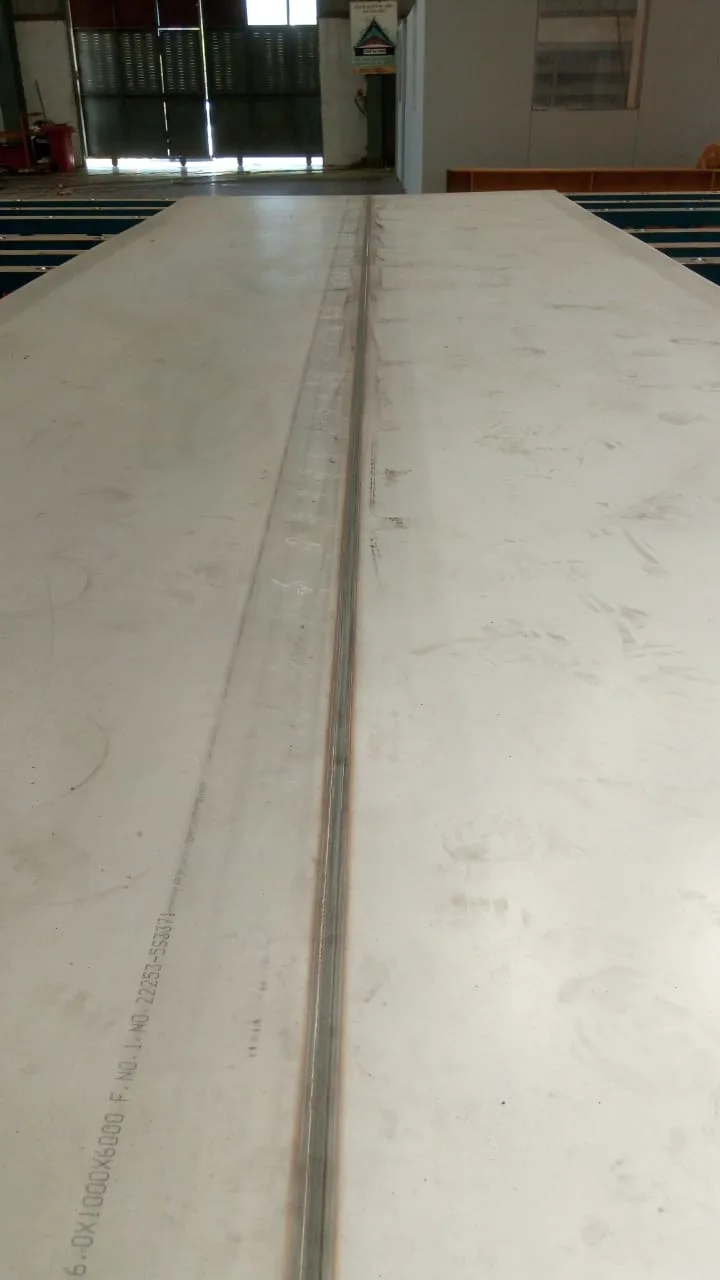

S.W.A.T (SigmaWeld Accelerated TIG) is a keyhole welding mode available upto 1000Amps. Increasesthe speed of welding upto 100% compared to traditional GTAW process. No edge preparation upto 10mm required.

FAST,PRECISE, DEENDABLE

Current Source | S.W.A.T 500 PDC | S.W.A.T 1000 PDC |

|---|---|---|

Welding current adjustment range, A | 3-500 | 3-1000 |

Current strength at 100% Duty cycle(40″ C), A | 500 | 1000 |

Supply mains voltage, | 400(+25%) | 400(+25%) |

Main frequency in the network, Hz | 50/60 | 50/60 |

Safety circuit breaker, A | 3⨯60 | (3⨯63)⨯2 |

Consumed current, A | 31Amps | 88Amps |

Max. power consumption, kw | 16.5 | 45 |

Efficiency,% | 96 | 96 |

Open Circuit voltage, V | 93 | 93 |

Welding machine dimensions (LxWxH), mm | 740⨯300⨯660 | 800 x 404 x942 |

Weight of the welding machine, kg | 60.0 | 90.0 |

Protection class | JIP 34 | IP 34 |

Insulation class | H | H |

APPLICATIONS

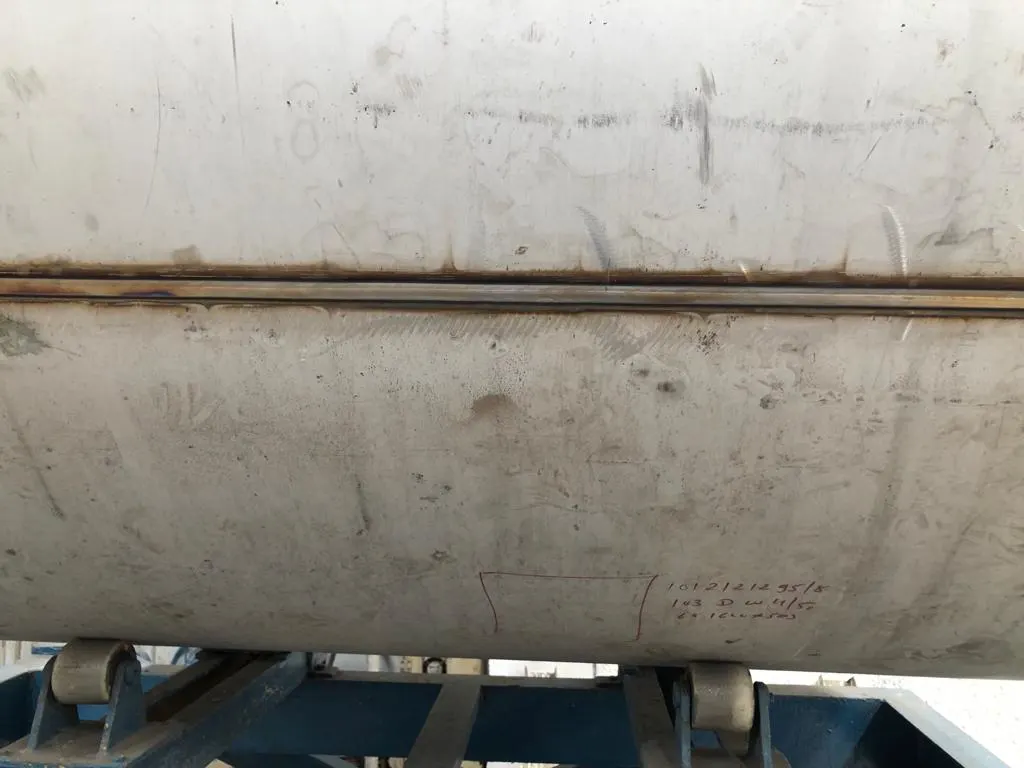

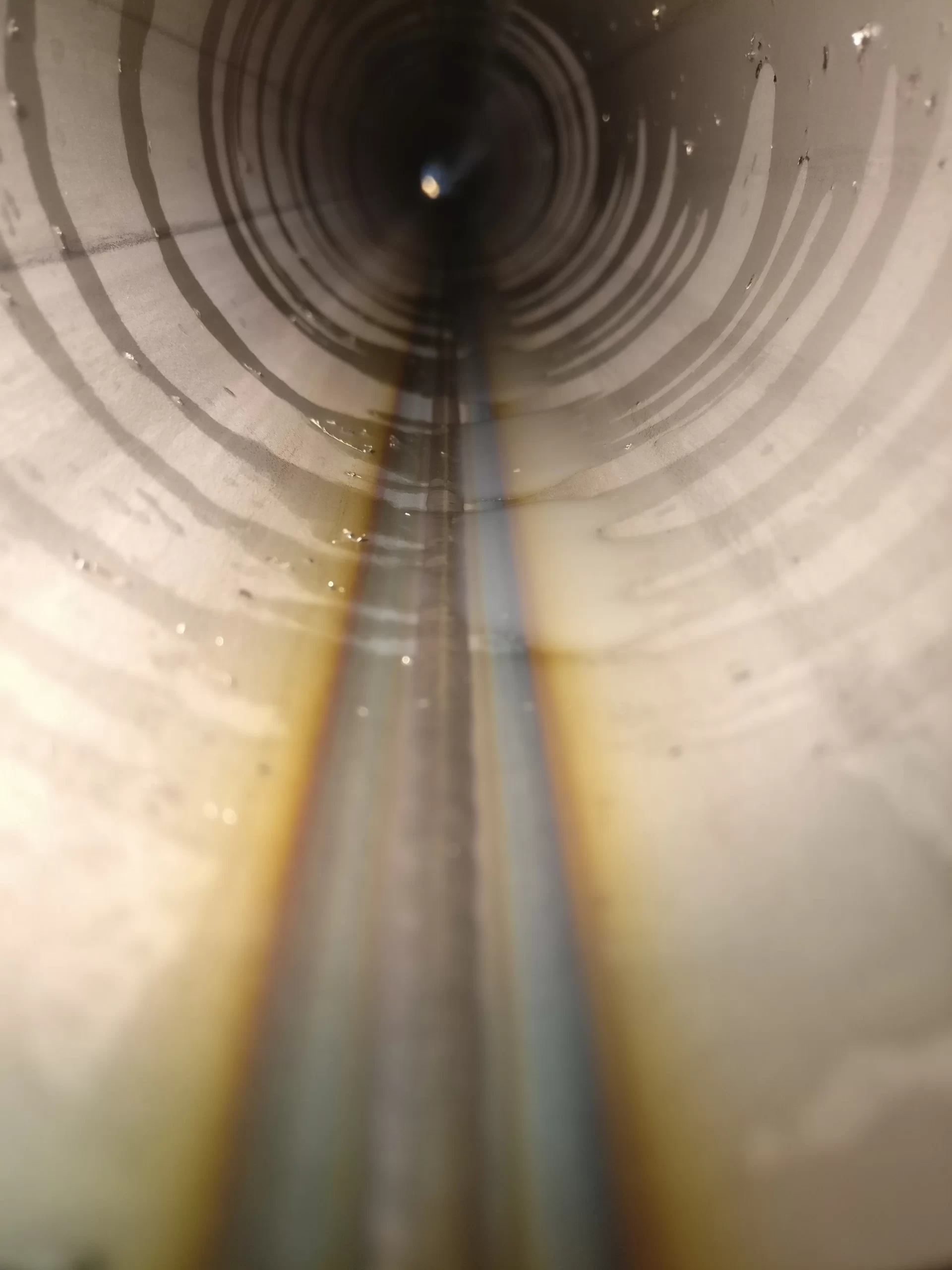

Tube Mills

Tanks & Vessels

Food, Pharma & Dairy Equipment

Aerospace

Nuclear

TIG welding has a new, accelerated and a highly-efficient process, and its aptly called SWAT – Sigma Weld Accelerated Tig.

EDWPL established full fledged welding automation division with design team based out of Pune office and execution team in Mumbai and Umbergoan

The Tungsten Inert Gas (TIG) welding process is a popular welding method used to join metals that require high precision and accuracy.