THE NEXT BIG THING IN TIG WELDING

The world knows that this is going to be India’s decade; perhaps the century will belong to

us. And for all good and right reasons.

India is one of the best-placed countries in terms of manufacturing excellence and

manpower. It has the best opportunity to serve the increasing international demand in

manufacturing segment – which is poised to grow YoY at 7% – 12% at least.

GTAW or Tig Welding is one of the cleanest, most preferred welding processes. It can be

easily automated and can be used in all positions. Yet, it is considered slow and expensive.

With the increasing demand for welding of exotic materials can this process be faster?

CAN IT REDUCE THE OVERALL COST OF WELDING FOR THE ENTIRE PROJECT? IF YES, HOW SO?

Manual welding in Tig involves using filler wires of 1 meter cut length. Of course, you know

it. The stub end of approximately 4 inches is unusable as the welder cannot reach it to the

arc safely. This is approximately 10% of the total filler wire consumption. So, for each Kg of

deposition required you need to buy 1.1 Kgs of filler wire. This makes the process expensive.

You know this too.

Manual welding speed is roughly 55mm to 60mm per min. in GTAW,

considering an 8mm thick single V joint. This itself would take 4 passes to weld.

Hypothetically, if the processed required to weld a long seam of 1.5 meters, the weld length

would be 1.5 meters x 4 passes – 6 long meters! At 60mm per min., it’d take at least 100 mins

of welding time, with waiting for filler wire start stops and inter pass temperature, which can

easily take up to 180 to 240 mins.

These questions, rather facts, are bothering. Right? But they need not…

The answer to all these questions is in affirmative, in favor of the manufacturer, especially

from these segments:

– Defense & Aerospace

– Tube Mills

– Cryogenic Vessel

– Tank & Vessel

– Food, Pharma & Dairy Equipment

– Nuclear

TIG welding has a new, accelerated and a highly-efficient process, and its aptly called SWAT –

Sigma Weld Accelerated Tig.

SWAT is an automated keyhole welding process that increases the speed of welding up to

100% compared to the traditional GTAW process, without the need for edge preparation for

materials up to 10mm.

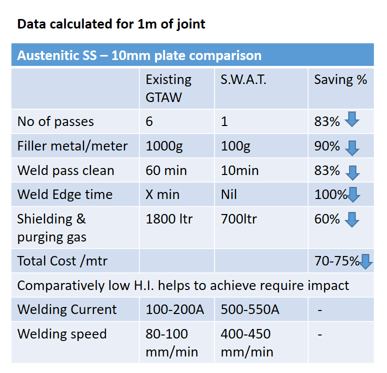

AUSTENITIC SS - 10MM PLATE COMPARISON

- 83% reduction in no of pass

- 90% reduction in filler metal consumption

- 83% reduction in cleaning time

- 100% reduction in weld edge preparation time

- 60% reduction in gas consumption

- 70-75% reduction in total cost considering all the factor like weld edge preparation cost ,filler metal cost, labour cost for cleaning setup & welding and gas cost.

- 30-40% reduction in H.I. helps to reduce HAZ and distortion in plate

HOW DOES SWAT WORK?

First and foremost, this technology and process is easy to learn and easier to adapt. Simply put, a highly concentrated arc punches through the material’s thickness forming a

keyhole, moving and carrying it through-and-through at almost three times the speed

compared to GTAW.

One of the leading features of the SWAT process is its constricted arc. It renders almost three

times the arc force – compared to GTAW – to melt the pool in the same energy parameters,

while delivering deeper penetration and lessening the effects of heat. The other benefits of

SWAT are that it requires low energy-input, has a very low distortion and can be used with or

without filler wires.

Now let’s compare SWAT with the existing GTAW process. You will observe that there is a

huge difference between the two, and that SWAT greatly reduces consumption of materials,

gas and preparation time.

Would it surprise if you are told that, in Tube Mill Application for example, welding through

SWAT is achieved at nearly double speed compared to plasma & TIG combination with

single torch single process, that too without any additional filler?

Each and every of the welds subjected to SWAT in Tube Mill Application were subjected to

the gold standard tests and configurations – RTR, flaring, bend, radiography. During these

tests, the SWAT process ran for multiple shifts, without any stoppage time and achieved the

same consistency every single time.

SWAT has delivered exceptional results to industries via productivity gains and cost savings;

not only in terms of lesser weld time and lower energy input, but also by its ability to weld

up to 14mm in a single pass, which in turn translates to savings in labour costs, consumables

and post-weld cleaning time.

SWAT is an application whose time has come.

related product

SigmaWeld Accelerated TIG (S.W.A.T)

Speedup your TIG Process up to 10X faster with SigmaWeld Accelerated TIG (S.W.A.T)