Thanks to the Induction Cookware, the concept of Induction is now d well known

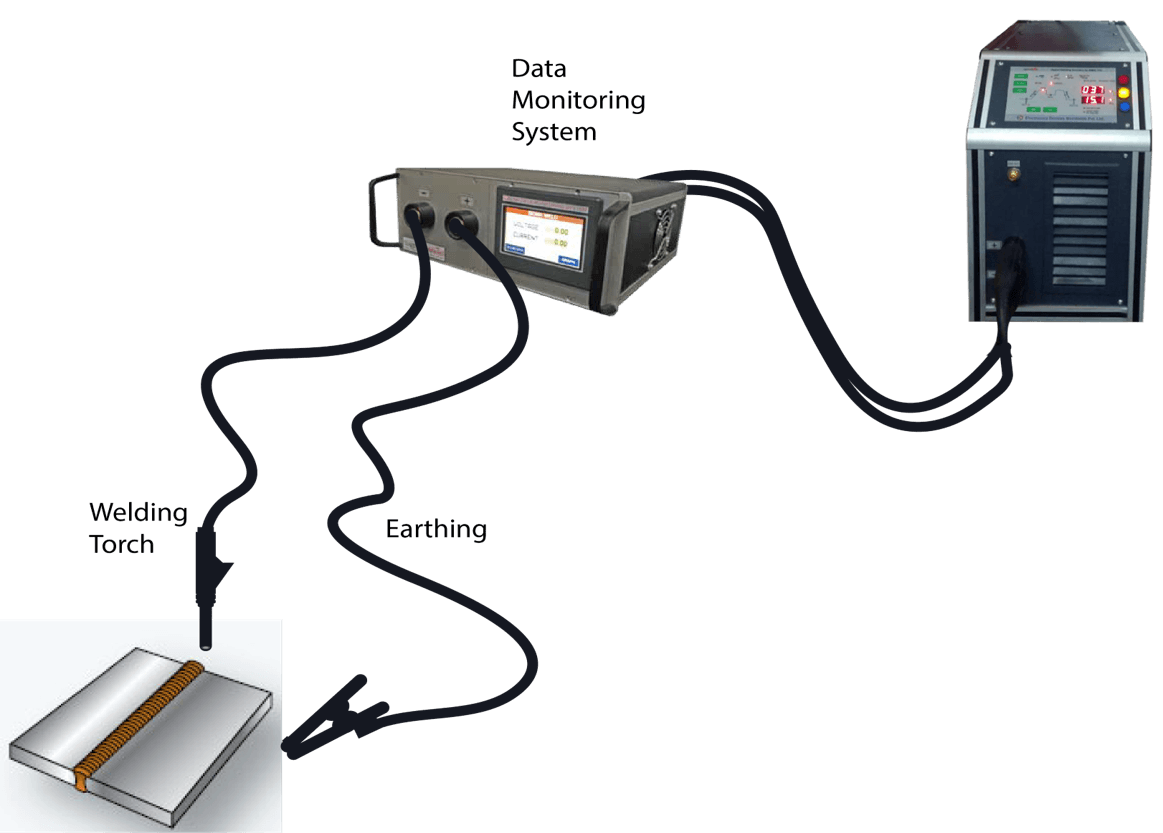

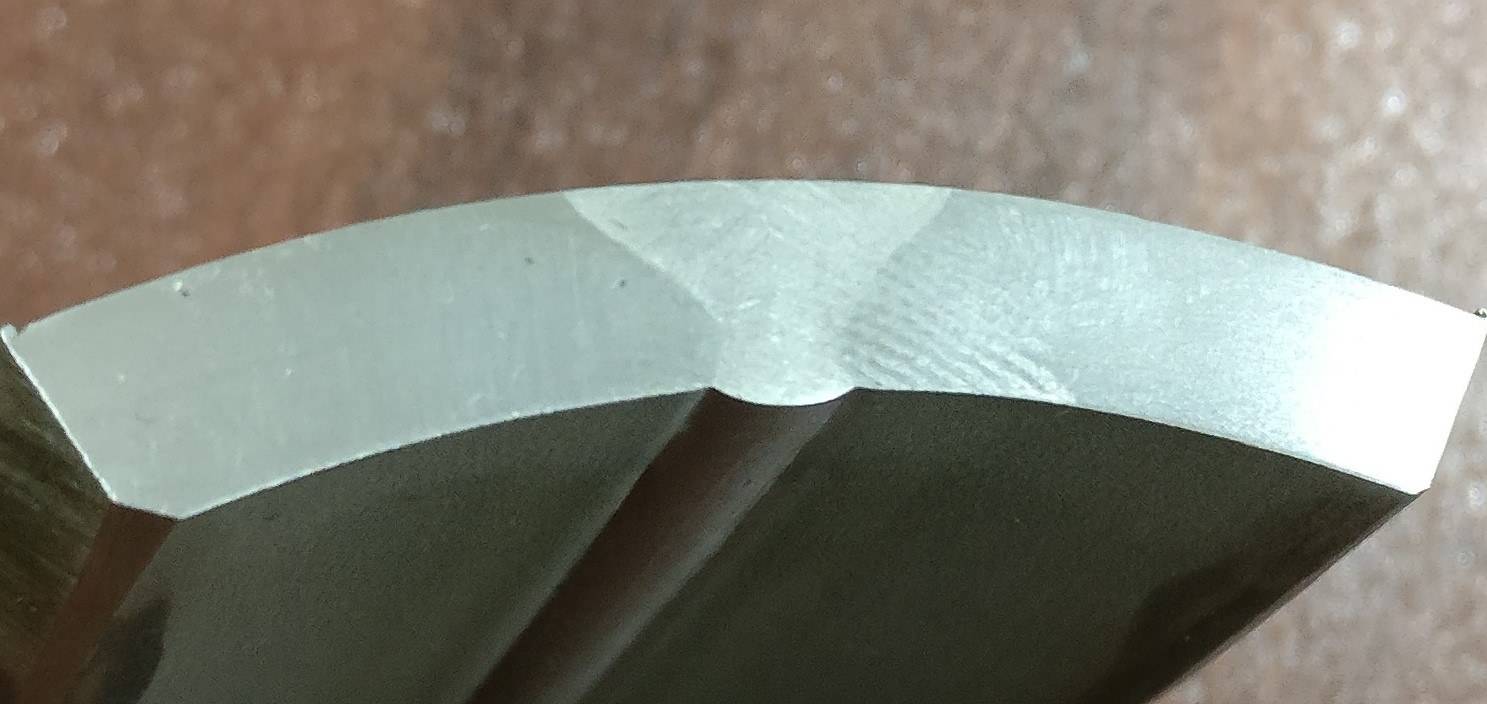

TIG welding has a new, accelerated and a highly-efficient process, and its aptly called SWAT – Sigma Weld Accelerated Tig.

Shrink fitting is a commonly used method for installing bearings on shafts or in housings. In this method, the bearing is heated to a high temperature and then cooled,

Each company wants to be able to make the most of the resources available to them. Often when out of turn orders are expected or a sudden surge in volume is likely to hit after a lean patch, the first reaction is to increase capacity, increase productivity at any cost.

The SigmaWeld Induction Heating Solution is an excellent example of how innovative technologies can revolutionize traditional manufacturing processes, resulting in increased productivity, reduced costs, and improved product quality. By adopting cutting-edge technologies like induction heating, manufacturers can stay competitive and stay ahead of the curve in today's fast-paced manufacturing industry.

EDWPL established full fledged welding automation division with design team based out of Pune office and execution team in Mumbai and Umbergoan. Having years of expertise in material handling and automation for induction heating , induction sealing and packaging automation, this was a natural expansion possible.

Welding is a process of joining two or more metals through heat and pressure. The Tungsten Inert Gas (TIG) welding process is a popular welding method used to join metals that require high precision and accuracy. TIG welding involves using an electrode made of tungsten to create an electric arc, which generates heat to melt the metal.