sigma weld accelerated tig

s.w.a.t

Single-pass, full penetration up to 10mm with zero edge preparation — convert multi-pass jobs into single-pass minutes.

30x Faster welding

From hours to Minutes

how is S.W.A.T Changing TIG Welding Forever ?

S.W.A.T delivers exceptional speed, cost savings, and weld consistency by redefining how TIG welding energy is applied to the joint.

Core Advantages of Sigma weld Accelerated Tig

Single-Pass Full Penetration

Achieves full penetration welds up to 10 mm in a single pass, eliminating multiple welding layers.

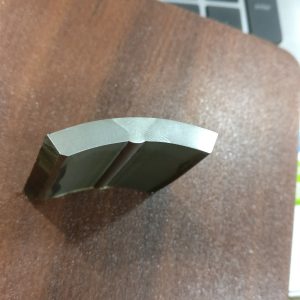

No Edge Preparation Required

Square edge joints can be welded without beveling or edge preparation up to 10 mm thickness.

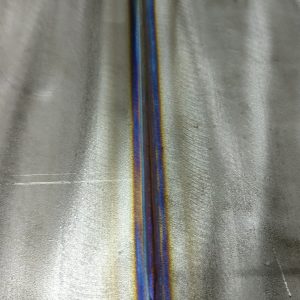

Keyhole TIG with Digital HF Control

High-frequency digital arc control (~150 kHz) generates a stable plasma keyhole for deep penetration.

Extremely High Welding Speeds

Enables welding speeds up to 300 mm/min on plates and ~400 mm/min in tube mill applications.

Radiographic-Quality Welds

Produces highly repeatable, X-ray quality welds validated through ASME Section IX testing.

Lower Heat Input & Minimal Distortion

Concentrated arc reduces heat input, minimizes HAZ, and lowers post-weld distortion.

Reduced Gas & Filler Consumption

Consumes as little as ~10% shielding gas and significantly reduces filler wire usage.

Automation & Production Ready

Designed for tube mills, orbital welding, and automated production lines using a single TIG power source.

100%

Weld edge preparation eliminated for joints up to 10 mm thickness

90%

Reduction in filler metal consumption for most welds up to 10 mm

83%

Fewer welding passes by replacing multi-pass TIG with a single-pass process

70-75%

Overall reduction in total welding cost due to faster cycle times

60%

Lower shielding gas consumption compared to conventional TIG welding

30-40%

Lower heat input resulting in reduced HAZ(Heat Affected Zone) and minimal distortion

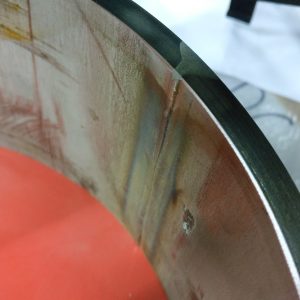

Pressure Vessels & Heavy Fabrication

Single-pass, full-penetration welds on thick stainless-steel sections

Radiographic-quality joints meeting ASME Section IX requirements

Eliminates edge preparation and reduces overall fabrication time

Tube Mills & High-Throughput Production Lines

Replaces PT-TIG welding with significantly higher line speeds

Consistent weld quality at continuous production rates

Designed for integration into inline tube and pipe manufacturing

Exotic & Reactive Alloy Welding

Proven welding of titanium, nickel, cobalt, and alloy steels

Low heat input minimizes distortion and metallurgical degradation

Stable arc control ensures repeatable, high-quality welds

Automated & Orbital Welding Systems

Fully compatible with orbital heads and mechanized torch systems

Consistent penetration and weld profile in automated environments

Ideal for high-repeatability and precision welding applications

| Parameter | Specification |

|---|---|

| Welding current adjustment range | 3 – 500 A |

| Rated output @ 100% duty cycle (40°C) | 500 A |

| Supply mains voltage | 400 V ±25% (3-phase) |

| Mains frequency | 50 / 60 Hz |

| Maximum power consumption | 16.5 kW |

| Consumed current | 31 A |

| Efficiency | 96% |

| Open circuit voltage (OCV) | 93 V |

| Recommended safety circuit breaker | 3 × 60 A |

| Dimensions (L × W × H) | 740 × 300 × 660 mm |

| Weight | 60 kg |

| Protection class | IP 34 |

| Parameter | Specification |

|---|---|

| Welding current adjustment range | 3 – 1000 A |

| Rated output @ 100% duty cycle (40°C) | 1000 A |

| Supply mains voltage | 400 V ±25% (3-phase) |

| Mains frequency | 50 / 60 Hz |

| Maximum power consumption | 45 kW |

| Consumed current | 88 A |

| Efficiency | 96% |

| Open circuit voltage (OCV) | 93 V |

| Recommended safety circuit breaker | (3 × 63 A) × 2 |

| Dimensions (L × W × H) | 800 × 404 × 942 mm |

| Weight | 90 kg |

| Protection class | IP 34 |

A range of optional accessories to support high-duty-cycle operation, improve process control, and enable automation across diverse welding applications.

External Water Chillers

High-capacity water chillers designed for continuous high-amperage welding operations. Recommended for applications requiring 100% duty cycles.

Remote Pendants & HMIs

Handheld remote pendants for welding parameter control and data logging, along with larger HMIs for automation and production line integration.

Specialized Torch Heads

High-amperage torch heads, including water-cooled and automated torch options for tube mills and orbital welding heads.

Purge & Fixture Kits

Back-purge rings, gas flow control systems, and fixturing solutions to maintain clean weld roots suitable for radiographic-quality inspection.

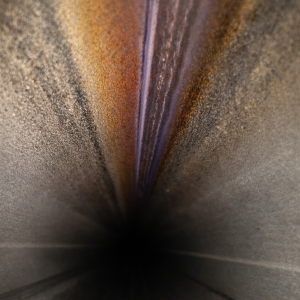

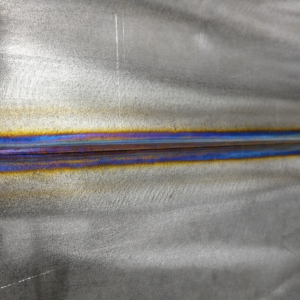

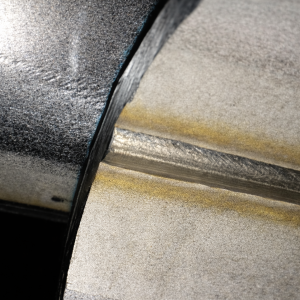

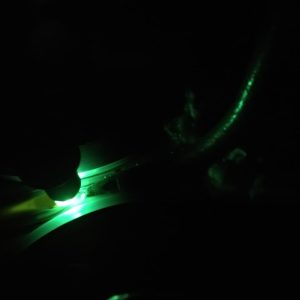

photo Gallery