STANDARD PRODUCTS

MAKING THINGS FASTER

SigmaWeld’s Standard Products range brings together proven MIG and TIG welding solutions engineered for industrial performance. Designed for reliability, consistency, and control, these machines support demanding fabrication environments where quality and uptime matter most.

SigmaWeld SW Series of MIG / MAG / FCAW

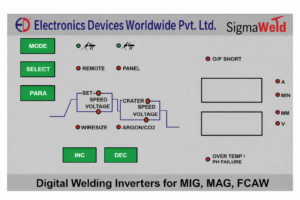

SigmaWeld is designed to meet varied requirement of the welding industry covering metal inert gas (MIG), (MAG), submerged arc welding and hard facing. Advanced micro controller technology enables sigma weld to have parameter locking technology which doesn’t allow welders to adjust the parameters beyond WPS settings.

Features:

SigmaWeld MIG welding inverters deliver a constant voltage output, even with mains power fluctuations up to ±15%. They operate reliably with generator power under balanced load conditions, ensuring uninterrupted welding performance.

Built on IGBT-based solid-state inverter technology with full-bridge topology, the machines offer superior weld control and long-term durability. Inbuilt protections against overvoltage, undervoltage, short circuit, thermal overload, and IGBT peak current ensure operator safety and extended equipment life.

Designed for ease of operation, welding parameters such as voltage and wire feed speed are easily adjustable and support 2T/4T modes. Advanced microcontroller technology enables parameter locking as per WPS, while an optional weld parameter recording system allows complete logging of voltage, current, and wire feed data.

| SPECIFICATIONS | INDY250MMA | INDY400MMA | INDY600MMA |

| Rated Input Voltage | 3∅ 415 V, ±15%, 50Hz | 3∅ 415 V, ±15%, 50Hz | 3∅ 415 V, ±15%, 50Hz |

| Power (KVA)@100% | 8KVA | 13KVA | 18KVA |

| Duty Cycle @ 40 C 1 | 250Amps @ 60% | 400Amps @ 60% | 600Amps @ 60% |

| Open circuit voltage | 60V | 80V | 80V |

| Output range | 50 to 250 Amps 16 to 30 Volts | 50 to 400 Amps 16 to 38 Volts | 50 to 600 Amps 16 to 40 Volts |

| (D⨯W⨯H)mm | 320 x 460 x 560 | 320 x 460 x 560 | 360 x 655 x 650 |

| Weight | 32kgs | 35kgs | 57kgs |

| SPECIFICATIONS | SW 2 R WF | SW 4 R WF | SW 4 R EWF |

| SW 4 R EWF | 0.8 ~ 1.2 | 0.8 ~ 1.6 | 0.8 ~ 1.6 |

| Wire Feed | 2 Roll | 4 Roll | 4 Roll |

| Feeding Rate | 2- 24 mtr/min | 2- 24 mtr/min | 2- 24 mtr/min |

| (D x Wx H) mm | 190 x 475 x 335 | 190 x 475 x 395 | 230 x 680 x 440 |

| Sigma Weld Mode | Wire Size | Output Range | Industry Application |

|---|---|---|---|

| SW250MM | 0.6 to 1.2 mm | 50 to 250 Amps / 16 to 30 Volts | Automobile, Light Fabrication, Furniture, Control Panel Manufacturers |

| SW400MM | 0.8 to 1.6 mm | 150 to 400 Amps / 16 to 38 Volts | Heavy Fabrication, Automobile, Structural Boiler, Pressure Vessels |

| SW600MM | 0.8 to 1.6 mm Solid / 2.4 mm Flux Cored | 50 to 600 Amps / 16 to 40 Volts | Heavy Metal Fabrication, PEB, Boiler, Pressure Vessels |

Protection,safety Features

| Thermal Shutdown | Inbuilt (Over temperature Indication) |

| Under Voltage | Inbuilt (Phase Failure Indication) |

| Over Voltage | Inbuilt (Phase Failure Indication/MOV) |

| IGBT Peak Current | In Built |

| VRD, Energy Saving | In Built |

| Cooling Type | Water Cooled |

| Water Cooling Interlocking | Water Flow Switch (Optional) |

| Output Short | Inbuilt (Phase Failure Indication) |

Features

| 1) Crater Voltage, Speed | Adjustable | |

| 2) Welding Mode | 2 T | 4T |

| 3) Digital Ammeter & Voltmeter | In Built | |

| 4) Process Memory Recall | In Built | |

| 5) Wire Feeder Motor | 2 Roll | 4 Roll |

| 6) Wire feeder Type Open Enclosed | Open | Enclosed |

| 7) Parameter Locking Remote | Optional | |

SigmaWeld SW Series of TIG / MMA / SMAw

This is a microprocessor based optimized design along with added features like adaptive hot start, arc force control, helps achieve seamless beads with all steels and alloy steels,. Welding with all types of electrodes such as 6013, 7018, SS316, SS308 or 6010 is also possible with ease.

Features:

The output of sigmaweld welding inverters are constant even if there is a power fluctuation int he mains of up to +-15 %. The power source equally works well on generator sets with balanced load. The output current does not even drop at 100 meters of copper cable length.

When the operator is not welding for more than 2 minutes, the power source automatically switches to low OCV output below 24V for safety of operator. This also leads to saving of no load losses.

The optimized design along with added features like Adaptive Hot Start, Arc Force Control, helps achieve seamless beads with all streels and alloy steels. welding with all types of electrodes such as 6013, 7018, SS308, or 6010 is also possible with ease.

Sigma Weld welding inverters are designed for Safety of both operator and machines, It has inbuilt protections for Overvoltage, Undervoltage, Output Short, Thermal Overload and IGBT Peak Current locking. This ensures longer life of equipment and our inbuilt Voltage Reduction Circuit which ensures OCV as low as 24 Volts or below when not welding keeps operators safe

| SPECIFICATIONS | SW250MMA | SW400MMA | SW600MMA |

| Rated Input Voltage | 3∅ 415 V, ±15%, 50Hz | 3∅ 415 V, ±15%, 50Hz | 3∅ 415 V, ±15%, 50Hz |

| Power (KVA)@100% | 7KVA | 12.6KVA | 22KVA |

| Duty Cycle @ 40 C 1 | 100% @200A | 100% @300A | 100% @400A |

| Open circuit voltage | 80V | 80V | 80V |

| Output range | 5-250Amps | 5-400Amps | 5-600Amps |

| (D⨯W⨯H)mm | 610×300×500 | 610×300×500 | 610×380×650 |

| Weight | 35kg | 35kg | 50kg |

<tdAmps

| MODEL | ∅ | Amps | Amps | |

| INDY170MMA | 1.6 | 30-55 | 50-75 | 20-45 |

| INDY170MMA | 2.5 | 50-100 | 70-120 | 40-80 |

| INDY170MMA | 3.15 | 80-130 | 110-150 | 70-120 |

| INDY250MMA | 4.0 | 120-170 | 140-200 | 100-150 |

| INDY400MMA | 5.0 | 150-250 | 190-260 | 140-230 |

| INDY600MMA | 6.3 | 220-370 | 250-320 | 200-300 |

WHAT DEFINES A RELIABLE WELDING STANDARD ?

Engineering Principles That Define the Standard

SigmaWeld’s standard MIG and TIG welding systems are engineered around principles that matter on the shop floor—stable power delivery, precise control, and integrated protection. By focusing on consistency under real operating conditions, these machines deliver repeatable weld quality, safeguard both operator and equipment, and support uninterrupted production. This is what defines a reliable welding standard: performance you can depend on, every shift, every weld. SigmaWeld’s standard MIG and TIG welding solutions are engineered around these fundamentals—providing stability, control, and reliability for real-world industrial welding environments.