INDUCTION HEATING MACHINE ( pwht)

Sigmaweld 40 kW PWHT System enables precise pre-weld and post-weld heat treatment using advanced induction technology. Designed for controlled pre-heating (100°C–300°C), post-heating (300°C–450°C), and stress relieving (450°C–760°C), it delivers uniform heating, reduced residual stress, and reliable weld integrity. Clean, energy-efficient, and safe — trusted since 1981.

Pioneers in Induction Heating Technology

Maximum Temperature

Up to 760°C

PWHT, stress relieving & normalizing applications

Rapid Heating

< 1.5 min to 150°C Significantly faster than flame or resistance heating

Energy Efficiency

70–90% Efficient

Direct induction heating into the metal

Safe & Clean Process

Flame-Free Heating

No soot, oxidation, or gas burner hazards

Temperature Accuracy

±5°C Precision

PLC-controlled heating with thermocouple feedback

Thermocouple Monitoring

Up to 6 Channels Simultaneous temperature logging

Technical Specificatins

| Parameter | Specification |

|---|---|

| Heating Technology | Induction Heating |

| Application | Pre-Weld, Post-Weld & PWHT |

| Maximum Temperature | Up to 760°C |

| Models Available | 5 kW – 200 kW |

| Power Supply | 3-Phase, 50 Hz |

| Temperature Accuracy | ±5°C |

| Heating Efficiency | 70–90% |

| Heating Time | < 1.5 min to 150°C |

| Control System | PLC-based Digital Control (HMI) |

| Thermocouples | Up to 6 channels |

Operating Modes & Pre-Programmed Cycles

Versatile control for every heating stage

Pre-&-Post weld Cycles

Optimized pre-heat, inter-pass temperature control, bake-out, and full PWHT cycles up to 760°C.

Intelligent Control Modes

Manual and temperature-controlled operation with PLC-based HMI for precise, automated heating.

Custom Cycle Programming

User-defined heating profiles with controlled heating, soaking, and cooling parameters.

WHY INDUCTION HEATING ?

Induction Heating

- High precision temperature control (±5°C)

- Flame-free operation for maximum safety

- 70–90% energy efficiency

- Fast and uniform heat distribution

- Clean process with no soot or oxidation

Flame heating

- Inconsistent temperature control

- Open flame poses safety hazards

- Less than 30% energy efficiency

- Slow and uneven heating

- Produces scale, soot, and surface contamination

APPliCATIONS

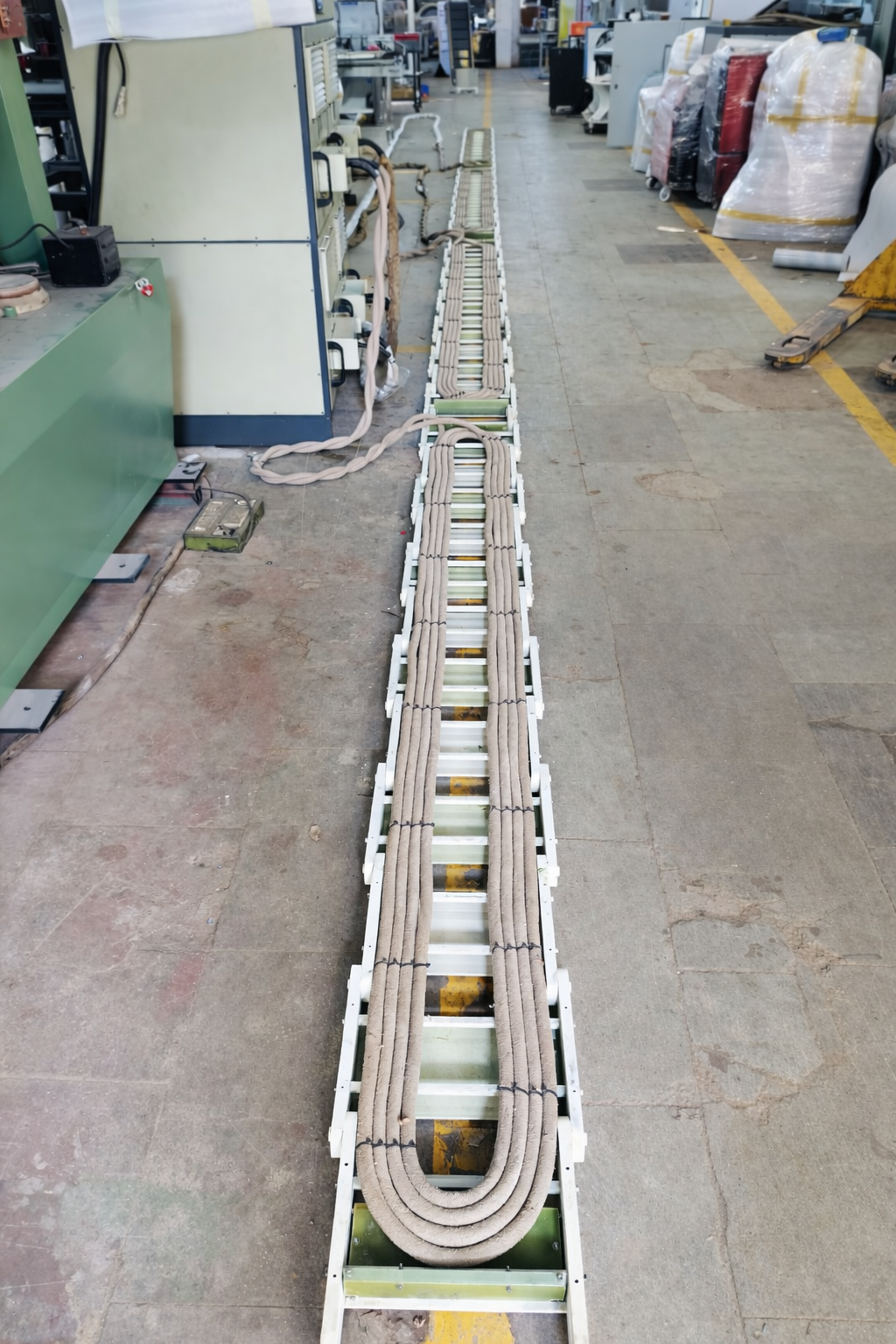

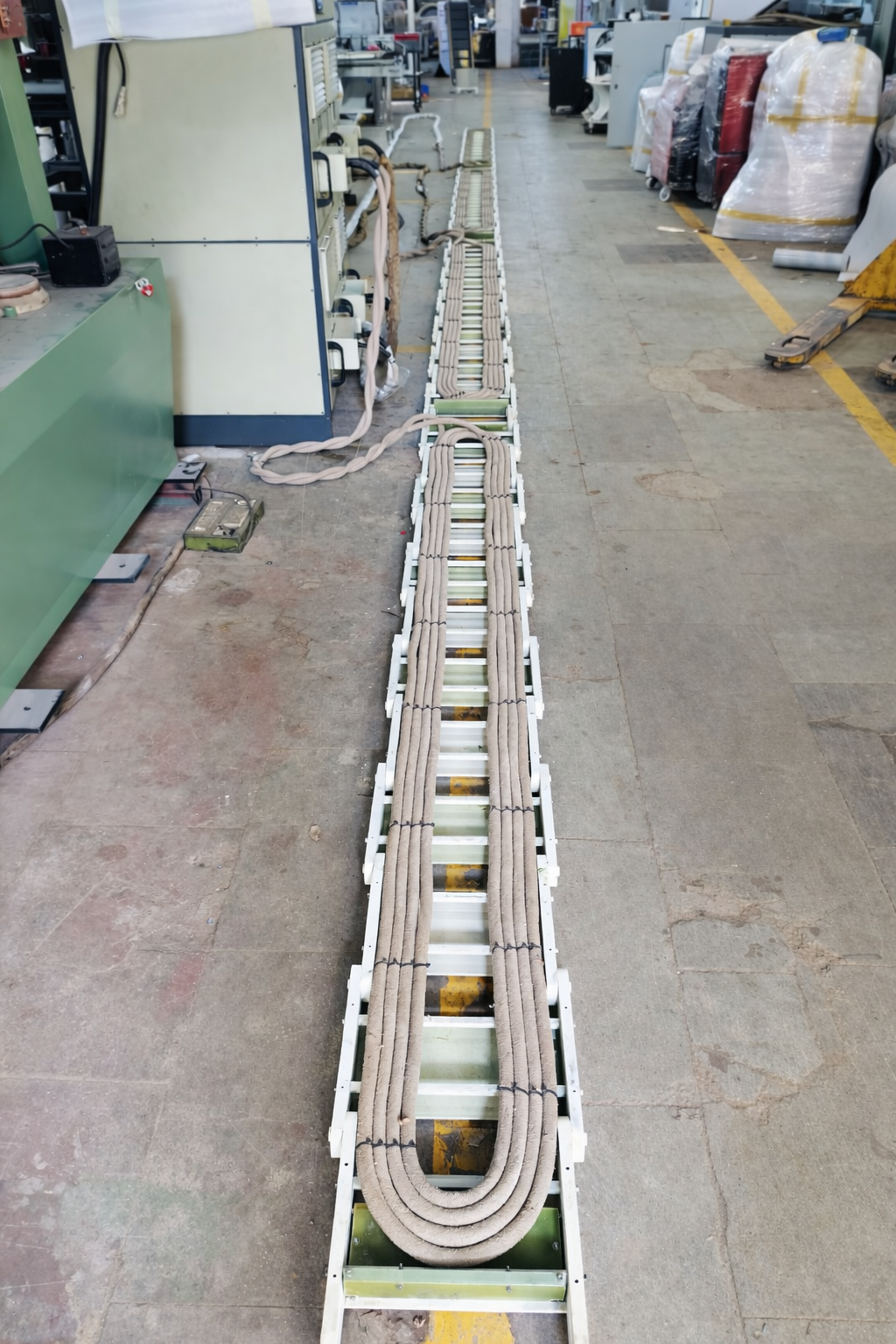

Pre-Weld Heating Applications

- Pipeline heating

- Long seam heating

- Circular seam heating

- Bucket tooth & plate preheating

- Stone crusher components

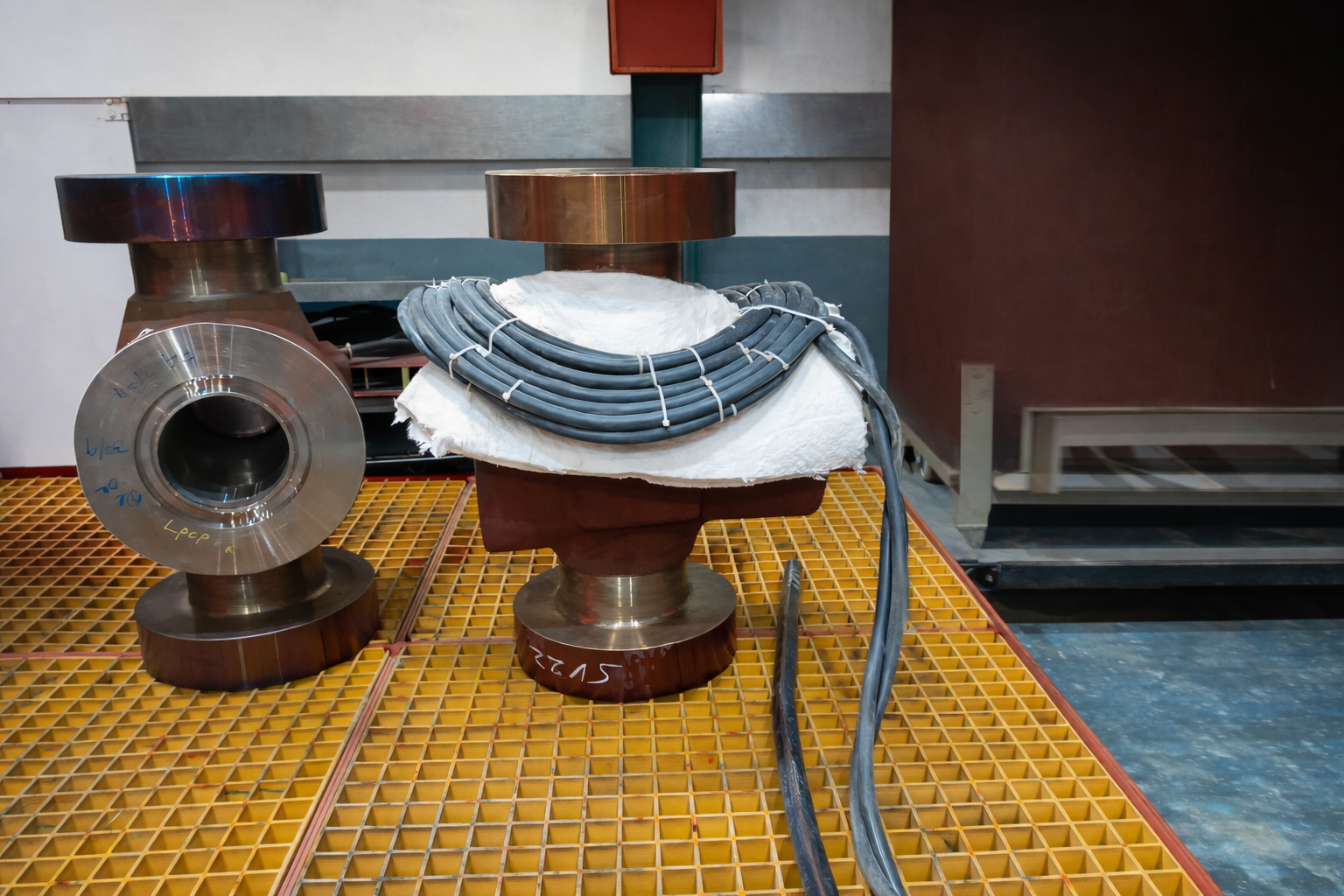

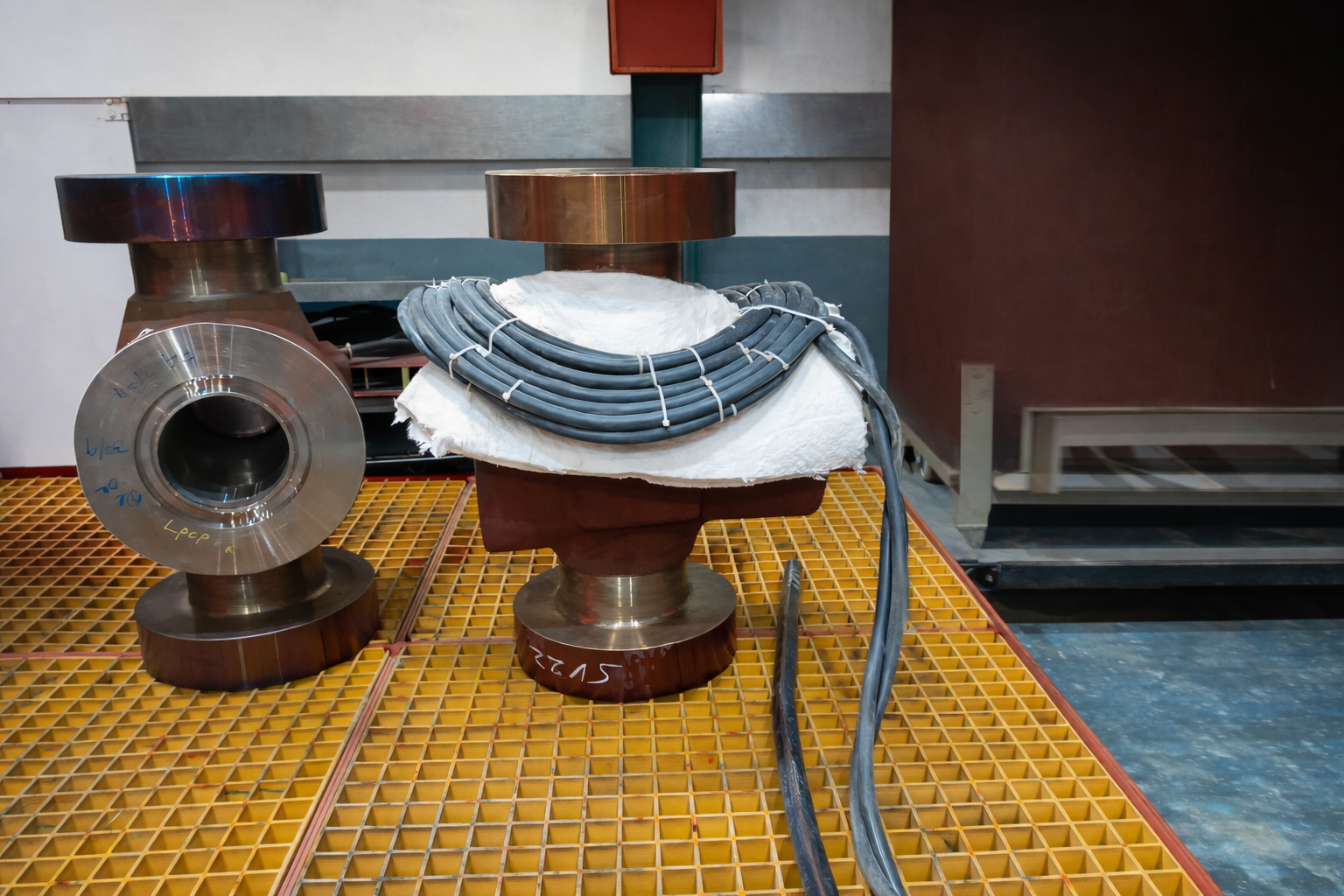

Post-Weld Heating Applications

- Nozzle Heating

- Normalizing Operations

- Circular seam heating

- Stress Relieving

- Pipeline heating

Industry Applications

- Power piping & P91 grade components

- Petrochemical plants

- Construction & repair pipelines

- Shipbuilding

- Heavy fabrication & shrink fitting

PHOTO gALLERY