EDWPL has been manufacturing and designing induction heaters since 1981, we have made equipment’s from 300Watts to 200kw. We make Sigma Therm induction heater for various applications such as hardening, brazing, shrink fitting, forging, annealing and pipe coating. We have developed the PWHT induction heater to specially cater to the welding requirements of pre and post welding treatment of metals with induction technology.

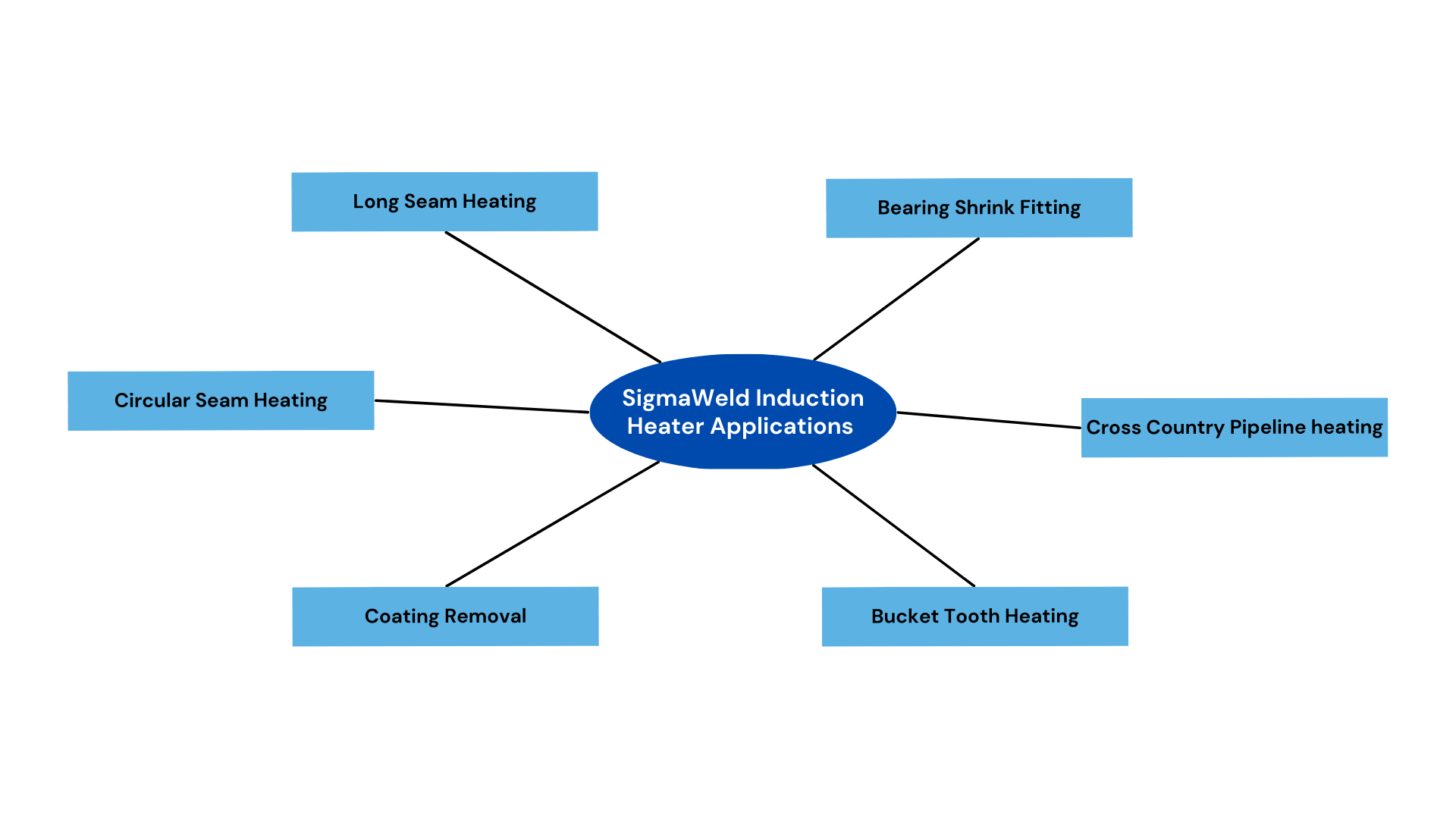

Sigmaweld induction heating system offers solution up to 100kw for Pre weld post weld Heat Treatment and shrink fitting Applications .

Clean green and safest way to pre weld, post weld heat treatment. Induction heating induces the heat directly into the metal, the heat is not conducted. This helps heat faster and with more efficiency. This method has very quick setup time and can preheat much faster than gas fired or resistance heating methods.

PLC based system with touch screen HMI controls the Sigma Therm to get the desired temperature profile. The advanced logic control helps achieve the accurate heating temperature Rate and maintain the cycle desired. The heating cycle can be programmed to ensure correct heating rate (DegreeC / HR), soaking temperature and soaking time,cooling ramp rate and cooling time. There are preset programs and any new heating cycle can be easily customized.

Flexible air cooled are available to wrap around and heat any shape, size of jobs. For pipes quick connect blankets are are also available in various sizes. Blankets are suitable for plant and onsite use they are manufactured from high temperature wear resistant materials. Customized blankets or coil can be designed to take care of specific requirements.

Temperature is thermo couple. If needed the temperature chart can be recorded in soft format or temperature chart can be printed. Upto 6 hermo couples can be interfaced with recorder. The temperature can be recorded, graphed and printed for reach cycle.

Sigma Therm PreWeld, Post Weld Heating Machines are rugged and built to work on generator sets or fixed supply lines. They are used onsite by mounting on trucks along with DG set and welding machines. The truck moves from joint to joint in the cross country layout of pipes. The setup and heating time is largely reduced thanks to quick connect wrap around coils. Typical heating cycles are under 1.5 minutes to reach 1 500C

Power Source – Sigma Therm PWHT – IH are available from 5Kw upto 60Kw for pre heating applications. The system can work in manual mode (Power % Setup)or Temperature control mode(Therm couple required).

Sigma Therm give power as per set power percentage. The cutoff level can be time based. Heating time can beset on the display panel(HMl). The heating remains ON for the duration of timer.

Specially designed quick connect induction blankets are available from 12inch upto 36inch pipes. These can be wrapped around and used for pre heating upto 2500C. Blankets consists of High temperature textile, Induction coil,Cerawool insulation, all stitched together.

Technical Specification | Induction: 20?C – 760?C |

Temperature Range | 5KW – 60KW |

Connection Voltage | 3-Phase 50Hz |

Safety

Substituting gas burners for pre heating of welding joints

Air Cooled Coil | 5m upto 30m |

Extension Cable | 5m / 10m / 15m |

Induction Blankets for Pre Heat | 6inch – 30inch |

Customized Coils | On request |

Thanks to the Induction Cookware, the concept of Induction is now fairly well known. Induction is a method by which heat is generated directly inside the metal, it is not radiated or conducted but Inducted.

The SigmaWeld Induction Heating Solution is an excellent example of how innovative technologies can revolutionize traditional manufacturing processes, resulting in increased productivity, reduced costs, and improved product quality.

Shrink fitting is a commonly used method for installing bearings on shafts or in housings. In this method, the bearing is heated to a high temperature and then cooled,