IOT – weldweb system

Quality assurance and cost reduction through real-time welding data

WeldWEB is an IoT-enabled welding monitoring system that continuously captures welding process data directly from the welding circuit. The system enables real-time visibility, traceability, and analysis of welding operations to improve quality control and reduce operational costs.

What Is the Need for IoT in Welding?

Modern welding requires high quality, consistency, and traceability, but traditional methods lack real-time visibility into critical parameters and WPS compliance. IoT-enabled welding monitoring solves this by capturing and analyzing live welding data, improving quality control, reducing rework, and enabling data-driven decisions.

key benefits

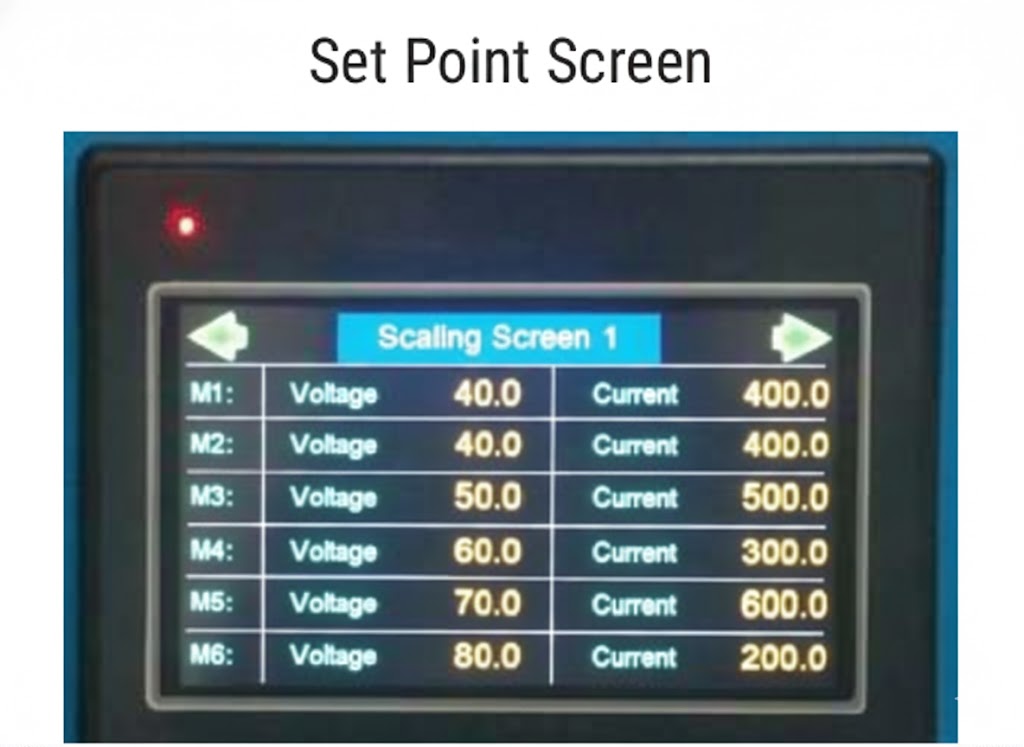

Continuously records critical welding parameters such as welding voltage, current, arc-on time, and shielding gas flow rate to ensure that welding remains within qualified WPS limits.

Provides real-time visibility and historical data analytics that support automation readiness, productivity improvement, and process optimization.

Enables verification that jobs were welded using approved consumables and qualified procedures, with complete deviation tracking and documentation.

SW WeldWEB provides a rapid return on investment through improved operational efficiency and reduction in rework-related costs.

key features

Real-time welding data capture, visualization, and control designed for quality assurance and operational efficiency.

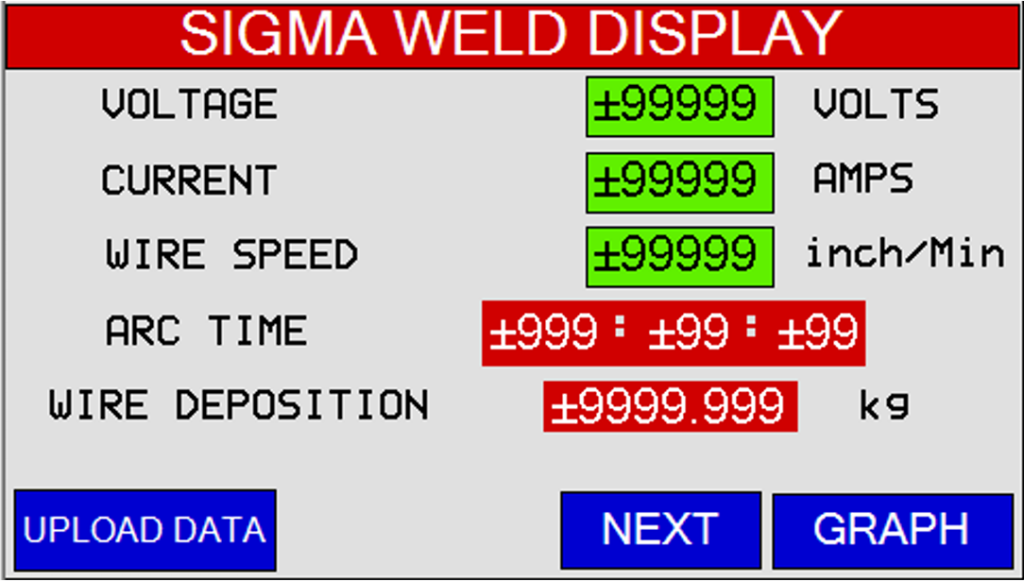

Parameters Captured by WeldWEB

Measured Parameters

Recorded directly from the welding power source or connected sensors:

Welding Current

Welding Voltage

Wire Feed Rate

Shielding Gas Flow Rate

Wire Size and Welding Speed (Automation mode)

INFERRED PARAMETERS

Parameters calculated using measured values:

Actual arc-on (welding) time

Heat input

Weld deposition rate

Material consumed vs deposited

inferred Parameters

Parameters calculated using measured values:

Actual arc-on (welding) time

Heat input

Weld deposition rate

Material consumed vs deposited

MEASURED PARAMETERS

Recorded directly from the welding power source or connected sensors:

Welding Current

Welding Voltage

Wire Feed Rate

Shielding Gas Flow Rate

Wire Size and Welding Speed (Automation mode)

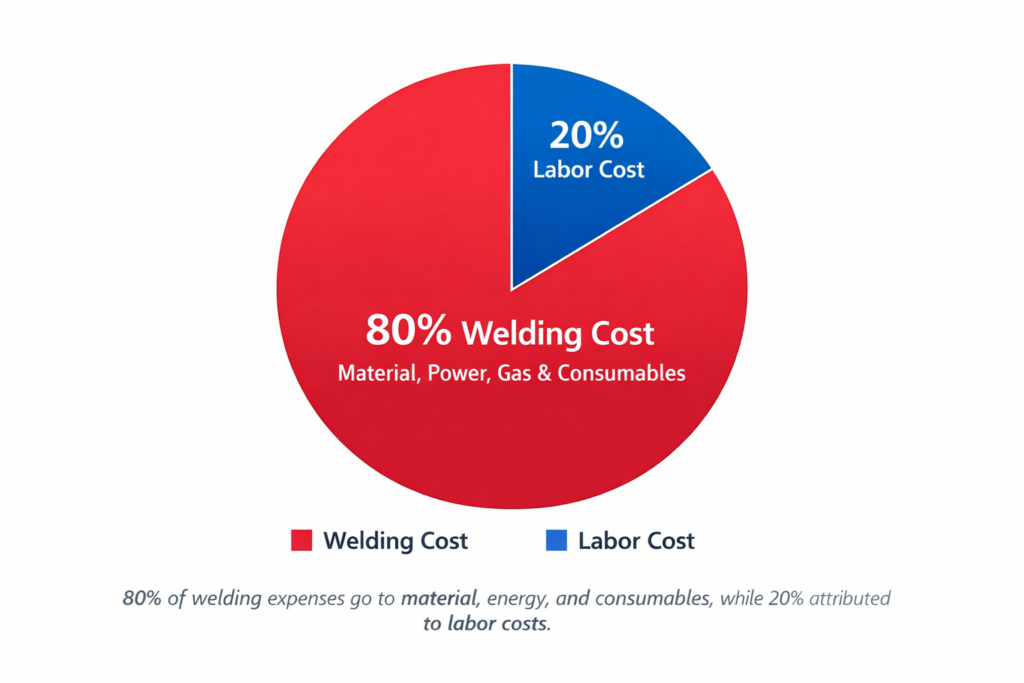

Welding Cost Reduction by WeldWEB

“Nearly 80% of welding costs come from material, power, gas, and consumables—making process efficiency critical. WeldWEB reduces these costs by detecting deviations early, preventing rework, and optimizing resource usage in real time.”

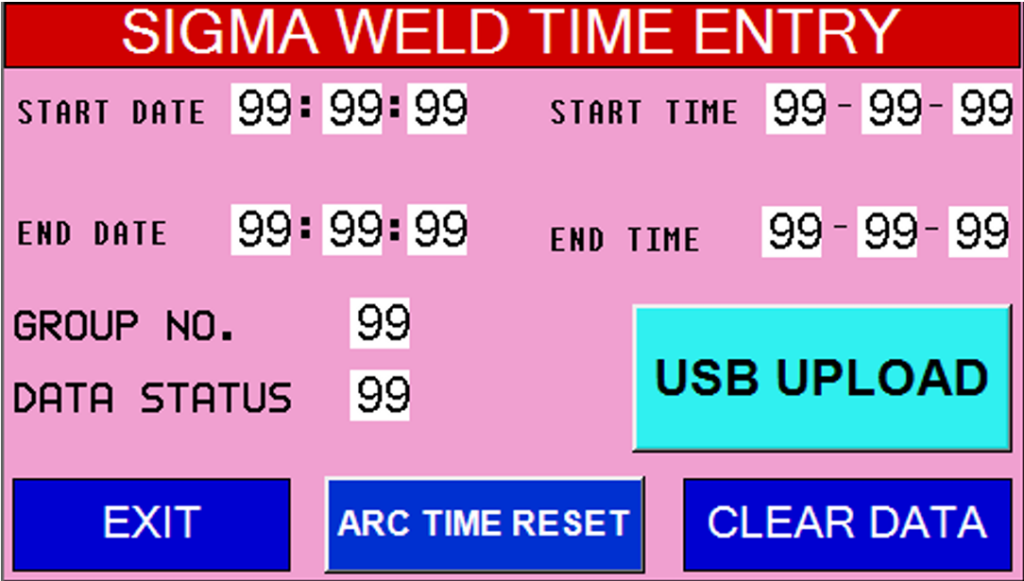

TECHNICAL SPECIFICATIONS

| Parameter | SW WeldWEB – Single Unit | SW WeldWEB – Multiple Unit |

|---|---|---|

| Technology | Microprocessor based Digital Inverter | Microprocessor based Digital Inverter |

| Input Supply | 230 V AC, 50 Hz | 230 V AC, 50 Hz |

| Display | 7" LCD Touch Screen | 7" LCD Touch Screen |

| Memory Capacity | 20 MB for Logging | 64 GB for Logging |

| System Available | Single Welding Power Source | Multiple Welding Power Source |

| Monitoring & Recording Data Type | Arcing Time & Non Arcing Time, Current, Voltage, Wire Feed Rate, Gas Flow Rate | Arcing Time & Non Arcing Time, Current, Voltage, Wire Feed Rate, Gas Flow Rate |

| Communication Port | USB and Ethernet | USB and Ethernet |

| Dimensions (L × W × H) | 340 × 245 × 130 mm | 340 × 245 × 130 mm |

| Weight | 5 Kg | 5 Kg |

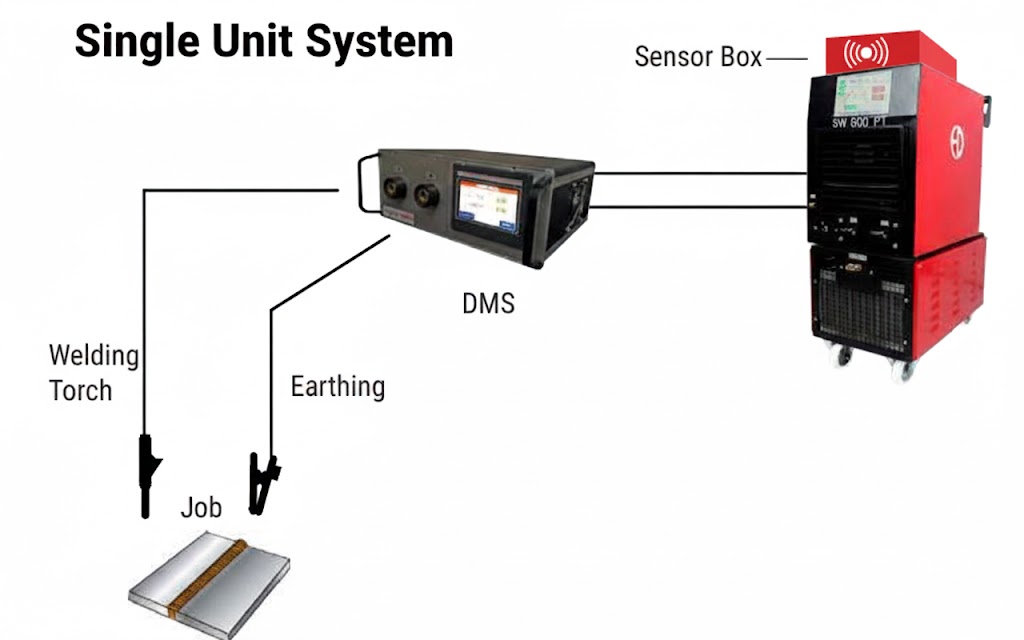

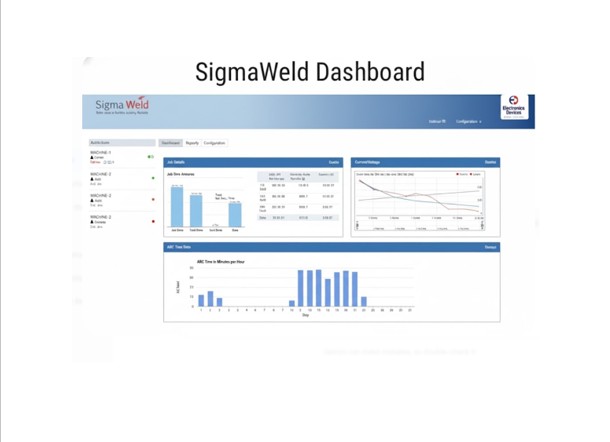

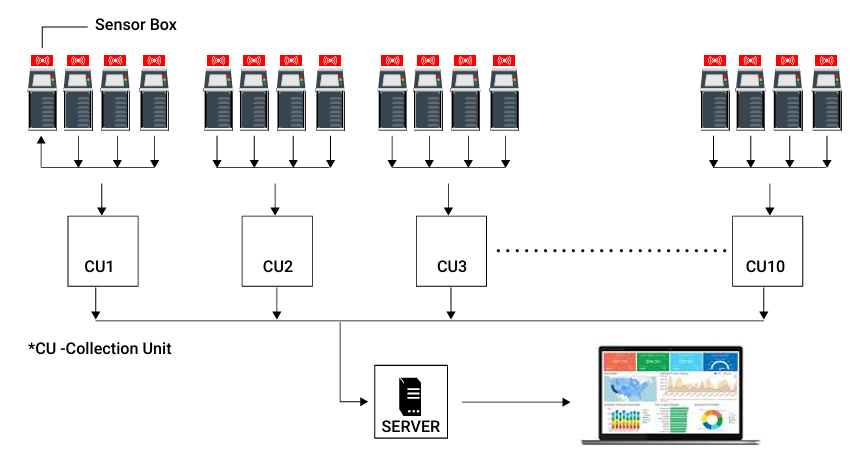

Multi-Unit System Architecture

Scalable IoT architecture for centralized welding data collection

SW WeldWEB Multi-Unit Architecture is designed for scalable, centralized welding data monitoring across multiple machines and shop-floor locations. The system seamlessly integrates sensor boxes, collection units, and a central server to deliver real-time visibility, traceability, and control of welding operations.

How the Architecture Works

Sensor Boxes acquire real-time welding parameters directly from each welding machine

Collection Units aggregate data from multiple Sensor Boxes at the shop-floor level

Central Server consolidates welding data for monitoring, analytics, and reportin

Designed for Scalability

- One server supports up to 10 Collection Units

- Each Collection Unit connects to up to 4 Sensor Boxes

- A single system can monitor up to 40 welding machines

System Capacity Overview

Central server architecture connecting up to 40 welding machines via collection units and sensor boxes

Scalable design: 1 server → 10 collection units → 4 sensor boxes per unit → 1 machine per sensor

Real-time data monitoring of voltage, current, and arcing time