Each company wants to be able to make the most of the resources available to

them. Often when out of turn orders are expected or a sudden surge in volume

is likely to hit after a lean patch, the first reaction is to increase capacity,

increase productivity at any cost. Usually, this hits the pockets a bit hard and

affects the usually bottom line. There isn’t enough time to think about and

know for sure if we are using the resources we have to the hilt. More often the

case is lack of enough data on the utility of resources. How much are the

machines used, how many hours did the welder actually weld on the job.

Sometimes you are doing a critical job and the customer wants to know exactly

what parameters, welding consumables have been used to do the job. How far

has the job progressed? How are you ensuring that the WPS is being followed?

What if all this data and more importantly its analysis is available on your

finger tips all the time?

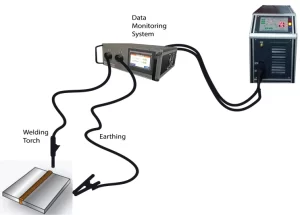

First step for any of this to happen is to have the DATA in place real time or

stored for each machine, each operator. This is now easily possible to have a

DMS (Data Monitoring System) that works like a black box and sits on your

existing machines collecting data. Each time the machine is switched on it

starts accumulating the data.

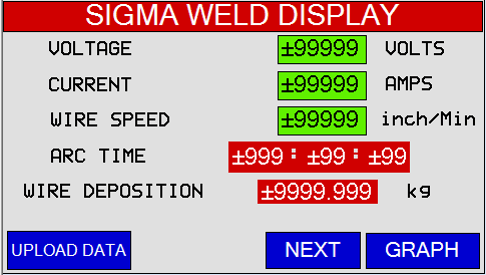

In case of welding equipments, critical data such as welding parameters of

Welding Current, Welding Voltage, Wire Speed (In case of MIG / SAW) can be

easily logged against a timestamp. Additional sensors can help add Gas flow,

5/21/2019 Welding Data Monitoring & Analysis Made Simple | Weldfab Tech Times

www.weldfabtechtimes.com/products-update/welding-data-monitoring-analysis-made-simple/ 2/4

Wire Speed and Welding Speed (in case of automation). This can be also

accompanied with the welder and machine data, so when the welder is about

to start the day he can login to the ‘DMS’ and enter his Name or Welder ID and

choose the welding consumable he is welding with (wire size and wire type in

case of MIG/ SAW). The DMS records at regular intervals (once / twice a

minute) the welding parameters, the welding consumable used in the weld

joint, the welder name who did the welding and if required also the job number

(part he is welding)

INDUSTRY 4.0 / IOT / WELD MONITORING SYSTEM /WELD DATA LOGGER