Welding Automation Solutions

Precision Welding. Automated Performance.

SigmaWeld automation systems convert manual welding into a controlled, repeatable, and high-productivity process—ensuring consistent quality, faster execution, and reduced operational cost.

Why Welding Automation Is Needed ?

Manual Welding Challenges

- Inconsistent weld quality due to human variation

- Slow production speed and delivery delays

- High rework and scrap costs

- Unsafe working conditions (heat, fumes, burn risks)

- Difficulty scaling operations for larger projects

What Automation Solves

- Delivers consistent, repeatable weld quality

- Reduces defects and rework

- Improves productivity and uptime

- Up to 2X higher throughput than manual welding

- Lower electricity and shielding gas consumption

Why Choose SigmaWeld Welding Automation?

SigmaWeld designs custom-engineered TIG & MIG welding automation systems tailored precisely to your job, material, and production requirements.

Application-Specific Engineering

Each automation system is engineered based on your job type, joint configuration, material grade, and thickness, ensuring precise and repeatable welding results.

Optimized for Productivity & Consistency

Automation parameters are optimized to deliver higher welding speed, stable arc performance, and uniform output quality across every shift.

Operator-Friendly & Industrial-Safe

Designed for easy operation, minimal manual intervention, and enhanced operator safety in demanding industrial environments.

Proven Across Heavy Industries

Successfully deployed across fabrication units, OEMs, pipelines, shipyards, and heavy engineering industries, delivering reliable performance in real-world conditions.

HOW SIGMAWELD DESIGNS YOUR AUTOMATION SYSTEM

Every SigmaWeld automation solution follows a structured engineering approach to ensure the system is perfectly aligned with your application, material, and production goals.

Understanding your component geometry, joint type, welding position, and quality requirements.

Selection of welding process and automation parameters based on material grade and thickness range.

Defining torch movement, part handling, positioners, gantry/robotic layout, and safety considerations.

Fine-tuning welding parameters, deposition rates, and travel speed for stable and repeatable results.

System integration with fixtures, power sources, and optional monitoring, followed by trial weld validation.

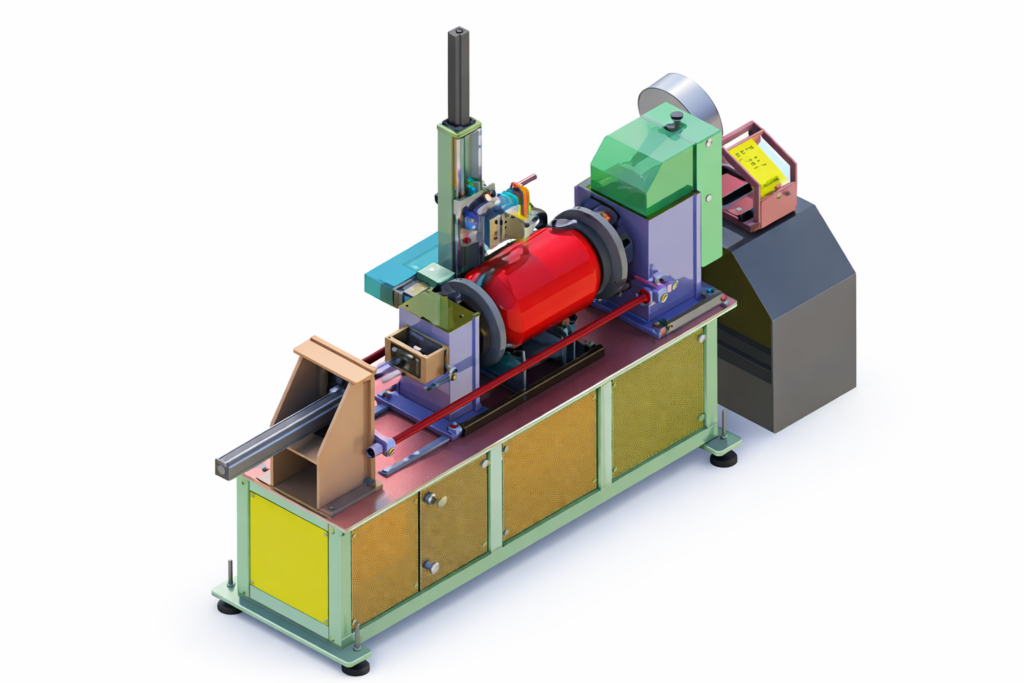

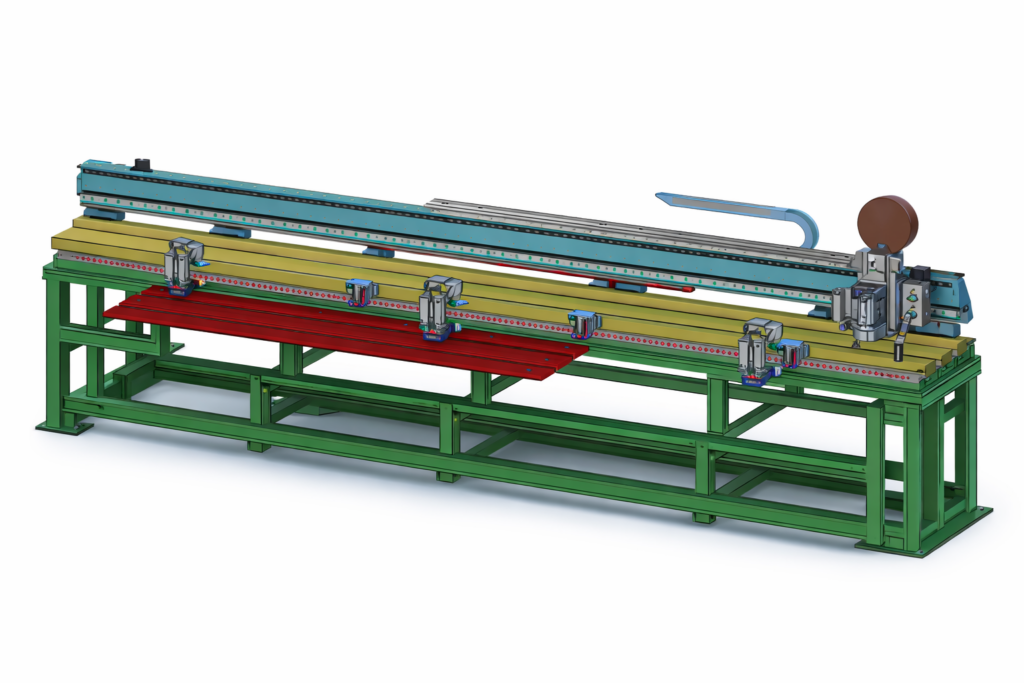

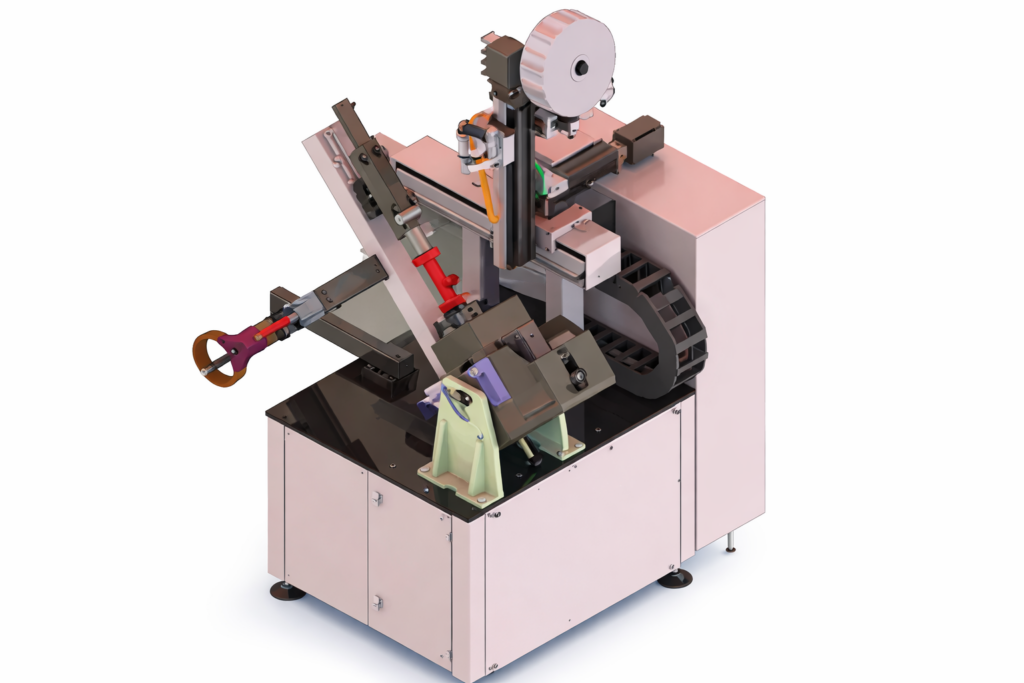

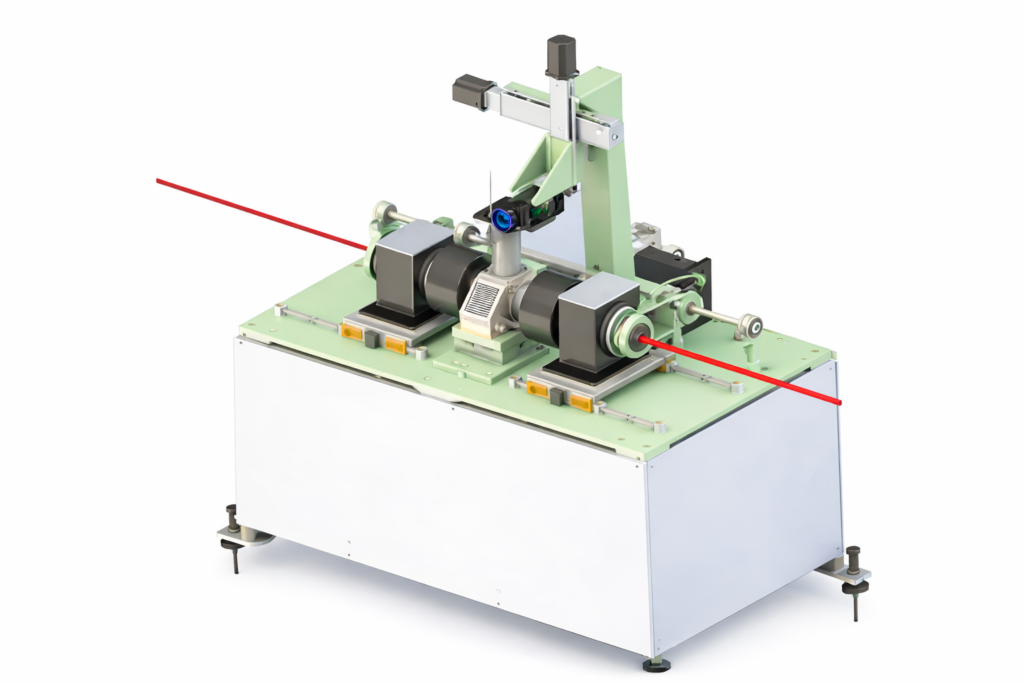

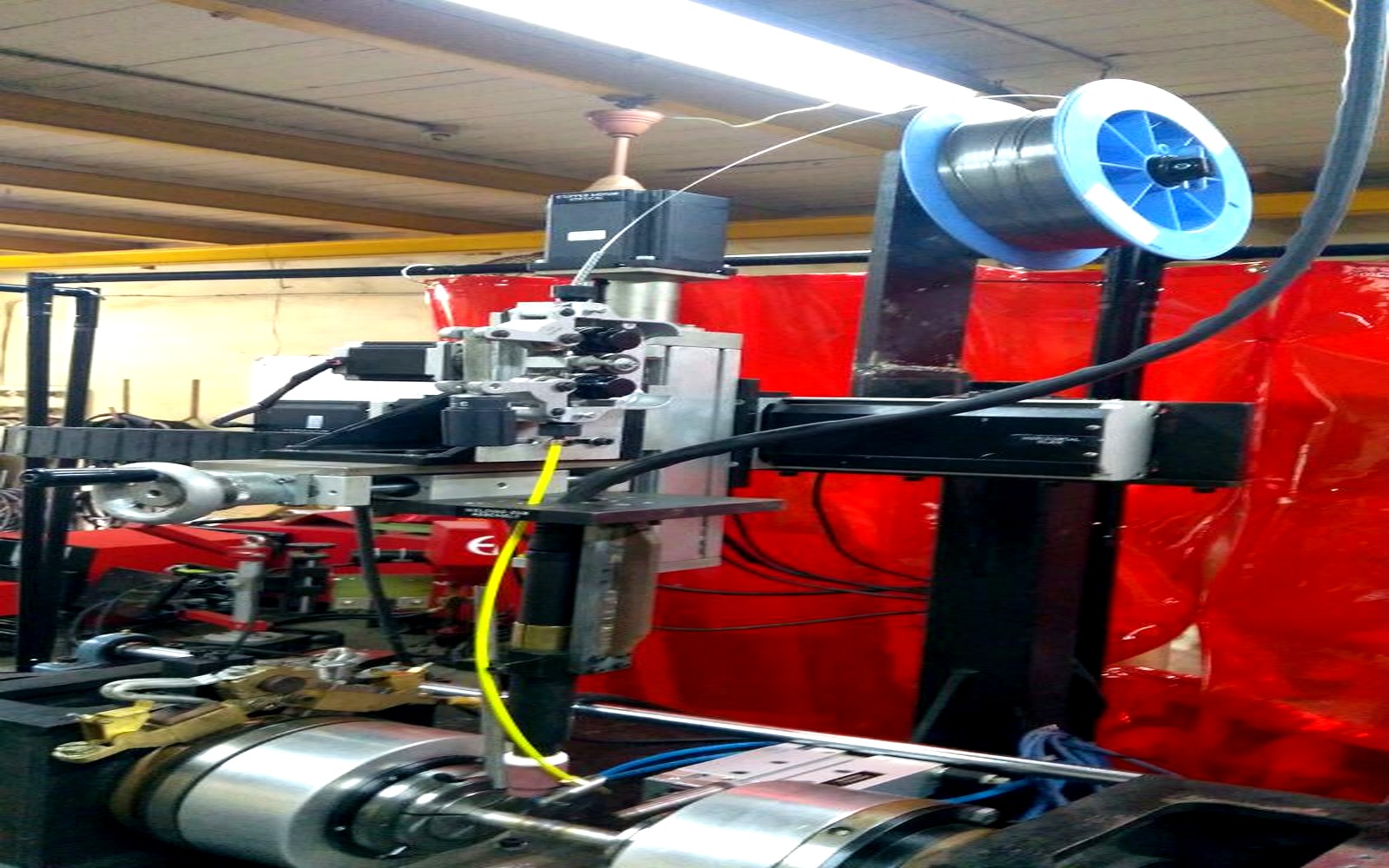

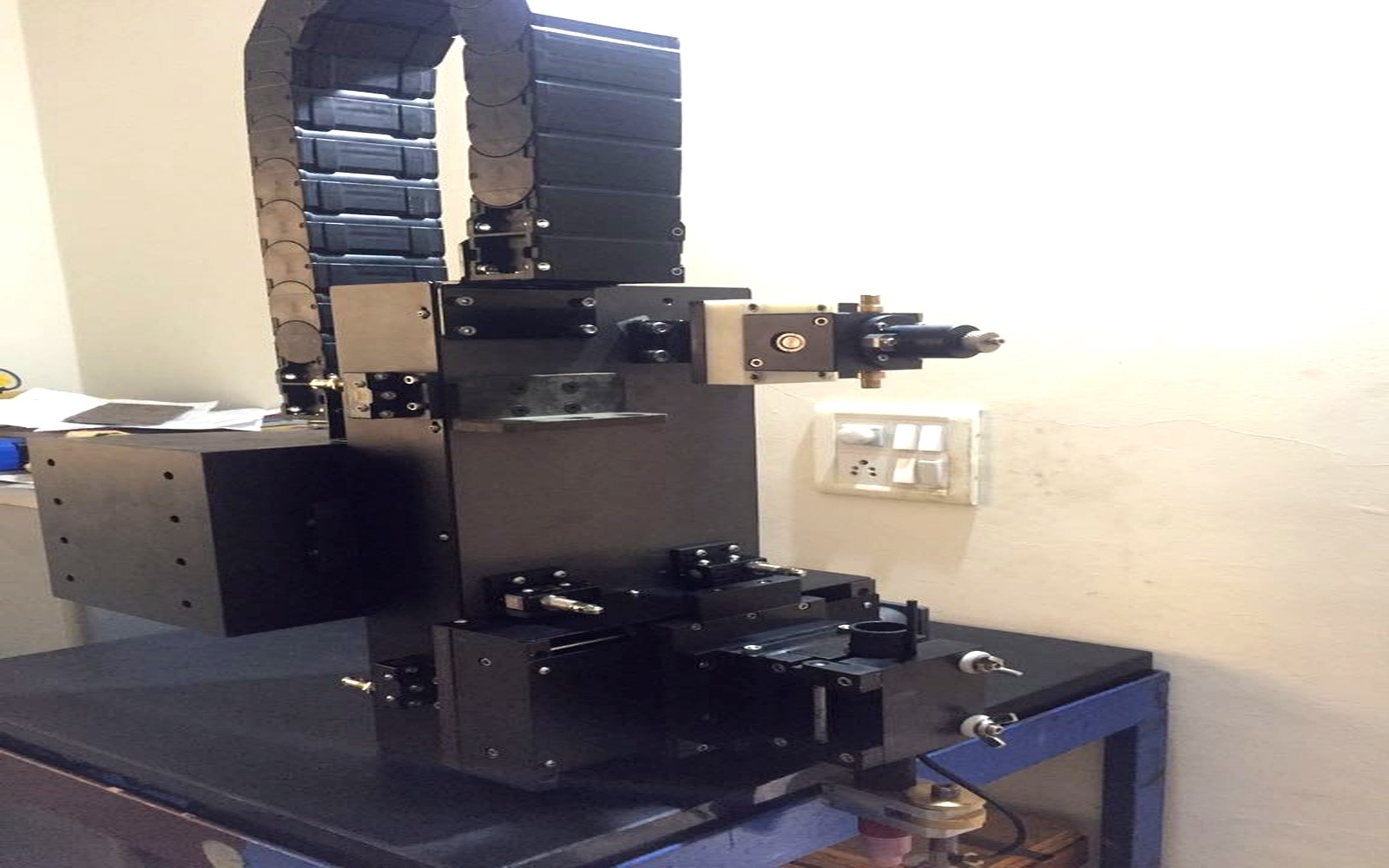

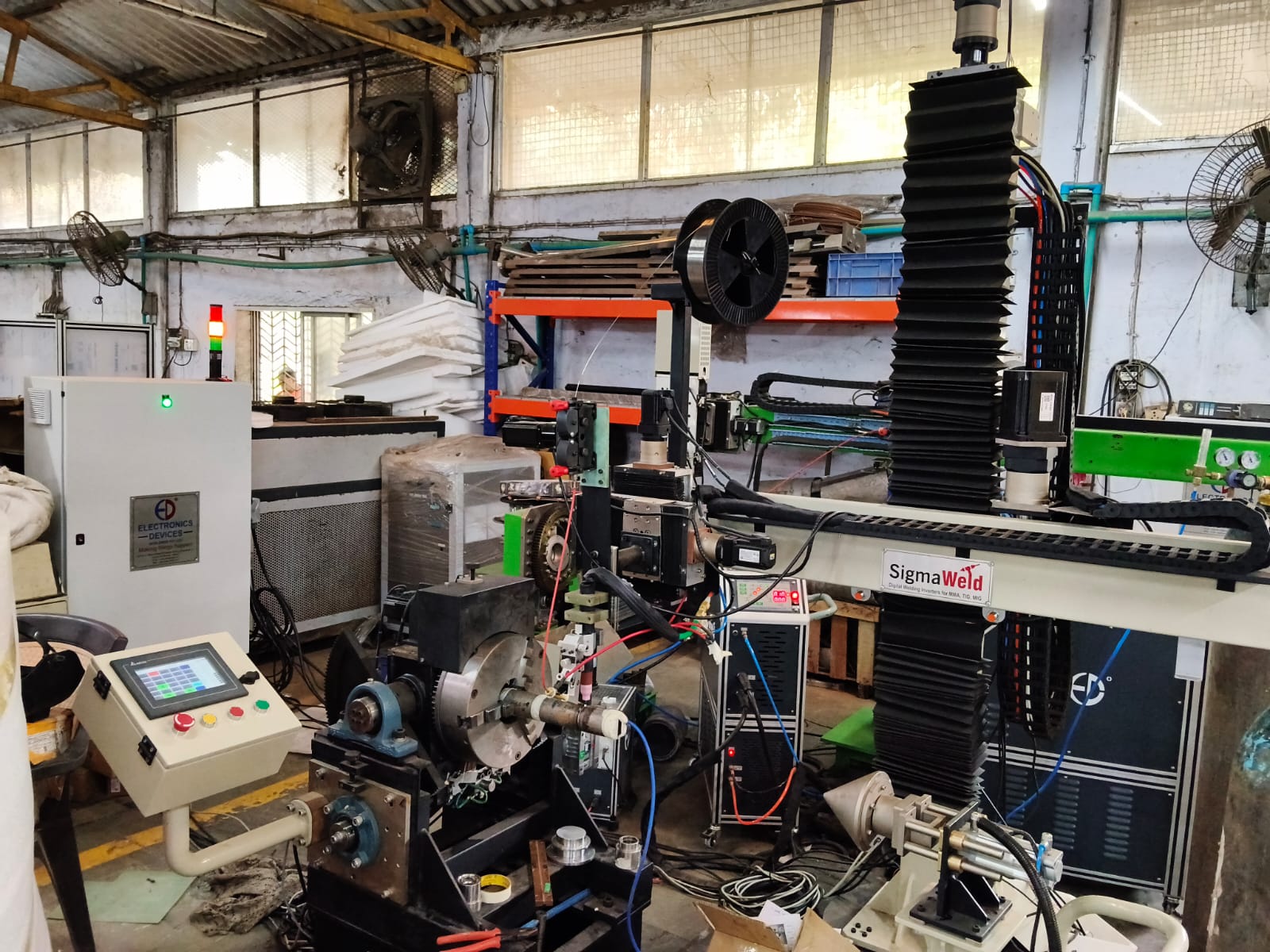

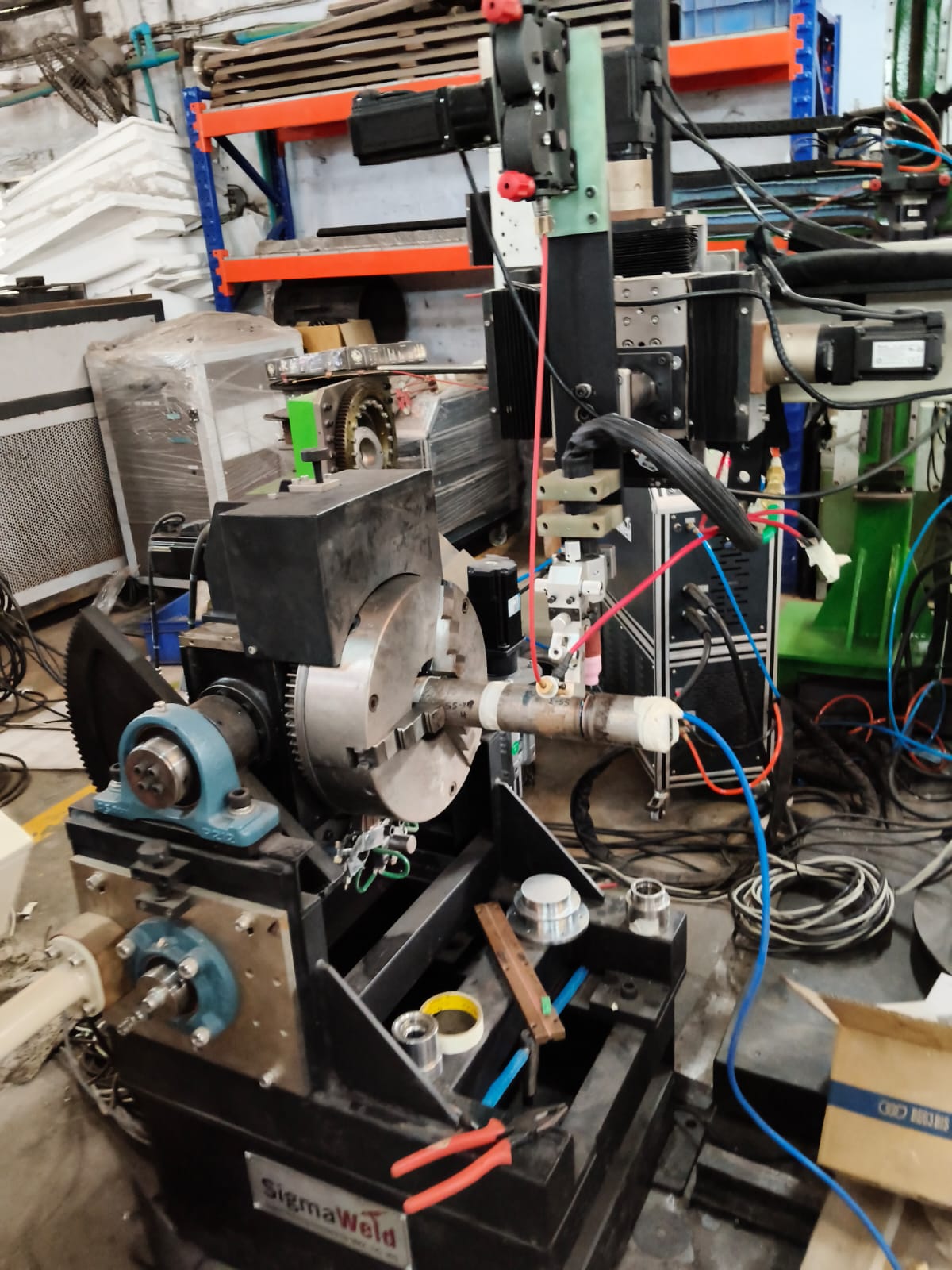

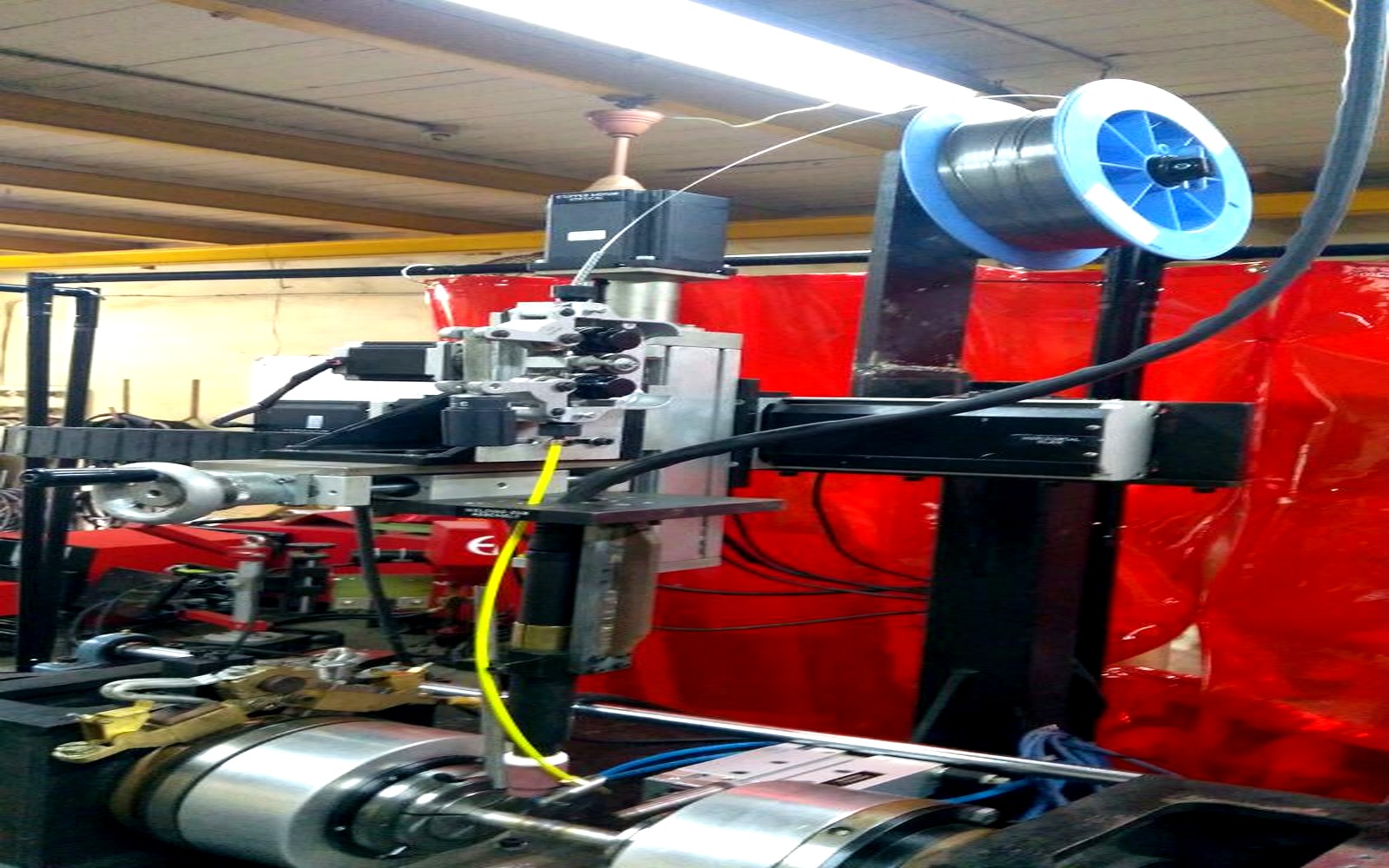

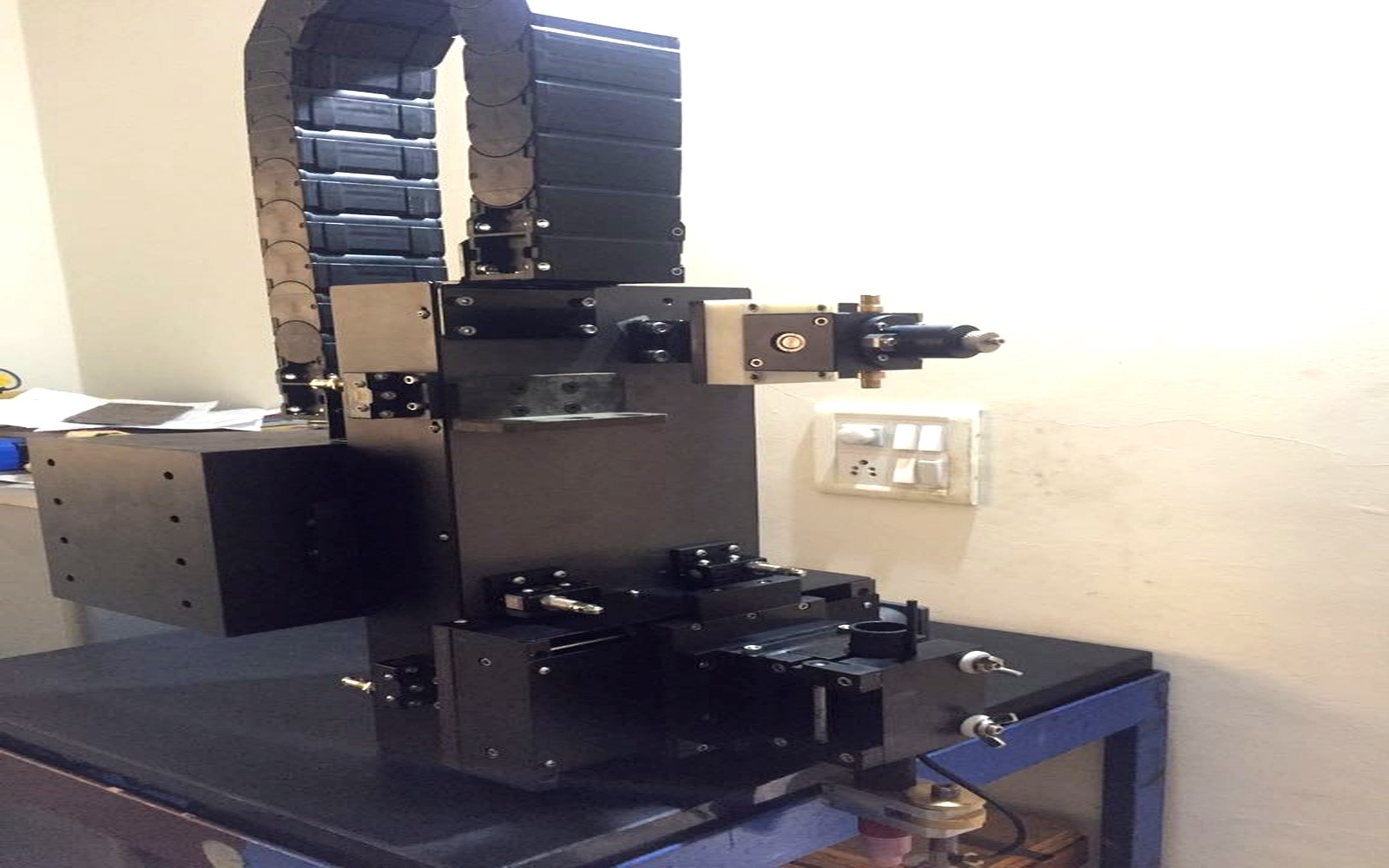

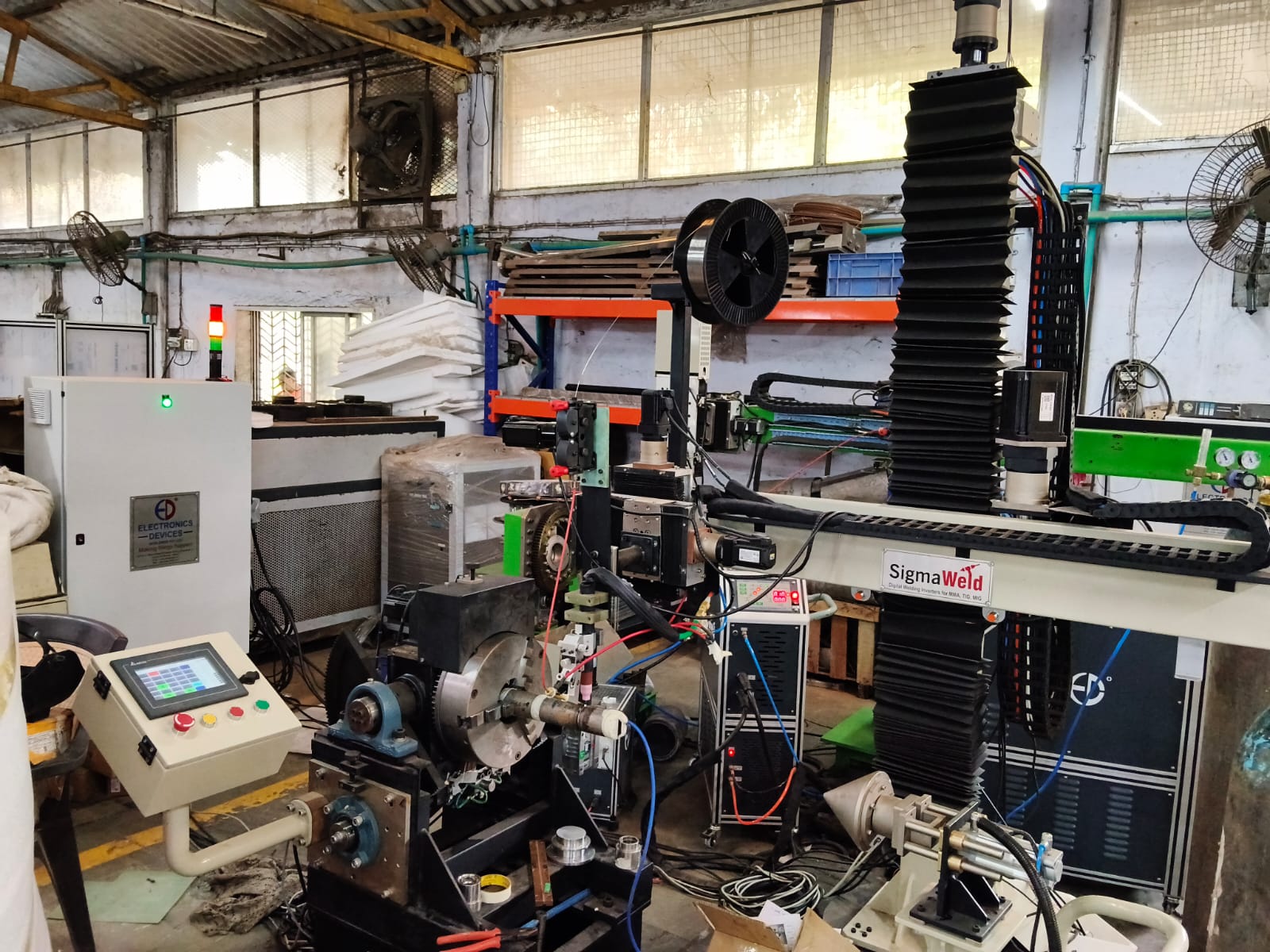

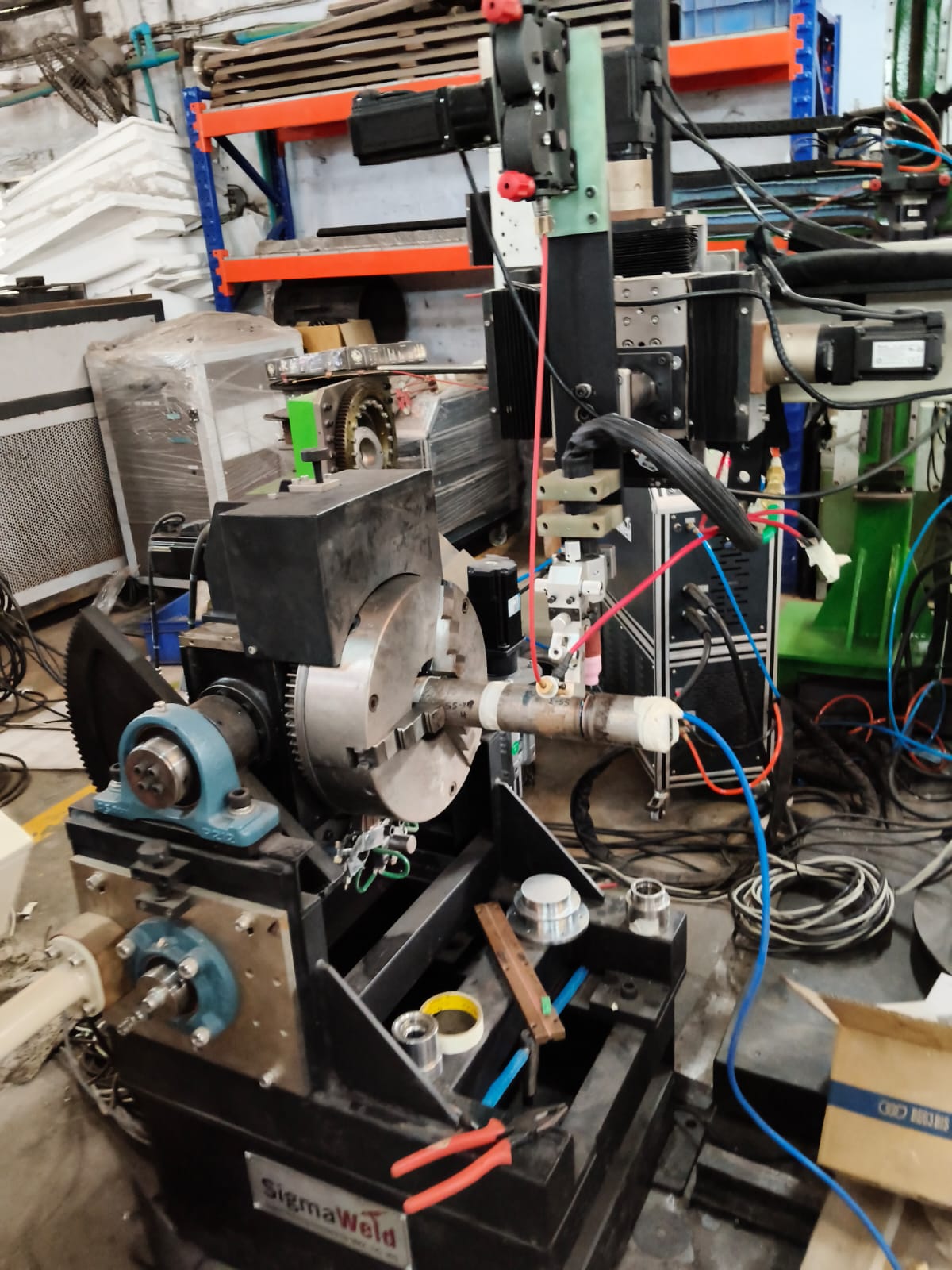

AUTOMATION GALLERY

Start Your Welding Automation Project

share with us :

To design a welding automation solution that precisely matches your application, our engineering team requires a clear understanding of your job, material, and production goals.

Please Share the Following Details:

Part drawings

(DWG / STEP / PDF formats)Component photographs

Including fit-up condition, joint access, and existing fixturesTarget production output

Per shift or per dayMaterial specification

Material grade and thickness rangeWelding standards

Existing WPS, quality requirements, or applicable codesInspection requirements (if applicable)

NDE methods and acceptance criteria

Once the details are submitted, our engineering team will review your application and propose a custom automation concept optimized for quality, productivity, and long-term reliability.